Burgmann Mechanical Seal (Germany)

Burgmann is undoubtedly the largest producer of mechanical seals and a leading provider of industrial sealing technology on the international stage. Burgmann’s comprehensive products and services are stand out in terms of quality and reliability in the world.

Most pump producing companies now use Burgmann mechanical seals to prevent fluid leakage. The standards developed by this company are also used by many other manufacturers of mechanical seals.

Burgmann Mechanical Seals are used in pumps, turbines, petrochemical industries and almost in any product that requires sealing.

The premium quality of Burgmann Mechanical Seals, close proximity to customers, the excellent innovational capacity and the extensive product portfolio for almost all industrial processes and applications are the factors that help Burgmann stand out in this industry.

As the most globally successful sealing solution provider, Burgmann offers the highest quality mechanical seal products and the best local customer service in the markets the company serves. The company also prides itself on prompt, effective and efficient handling of customer complaints and problems in all geographical locations.

Definition of Mechanical seal

Common mechanical seal names and terms include: fiber and spring, mechanical seal, and sealant. Basically, all electrical appliances through which liquids pass and have a moving shaft come with a sealing component that is used to prevent liquid leakage. These seals are generally divided into several classes, with graphite threads and Burgmann mechanical seals being the most widely used.

Burgmann mechanical seal is applicable in almost all industries. In fact, Burgmann mechanical seal plays a vital role in liquid sealing in all devices with a rotating shaft responsible for moving a liquid. In general, it can be argued that mechanical seal constitutes one of the key components of any electric pump and is primarily used to prevent liquid leakage into the electromotor.

Depending on their applications, mechanical seals are designed and produced by a variety of manufacturing companies in different industries. Shape and the material used to produce seals are the factors that are taken into account in the design process. In general, mechanical seals are divided into several classes such as agitator seals in pharmaceutical and chemical industries, oil seals in petrochemical industries, conventional seals that are mostly used for home and workshop applications, etc. of course it should be noted that the name assigned to each of the above mentioned categories may vary from one company to another. But in general, the above-mentioned classes come with the names referred to above.

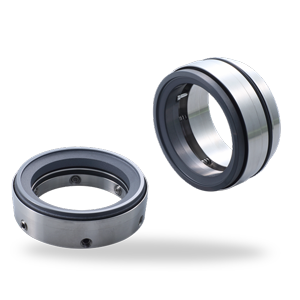

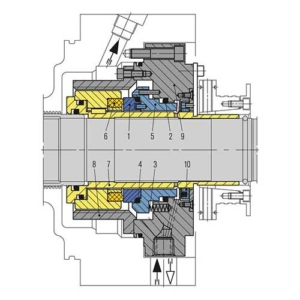

Components of Burgmann mechanical seals

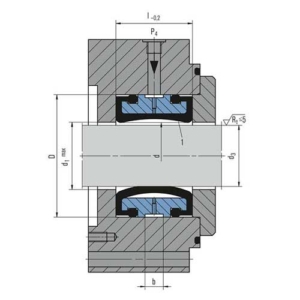

Mechanical seals, depending on their applications, have specific components, but the components that are generally shared by all mechanical seals include:

Seat

This component is fitted to the pump housing with a tight o-ring. This component is normally made of steel. Of course, depending on the application, the steel type may vary

Cone-shaped spring

This spring firmly attaches the face seat to the stationary parts and prevents the passage of liquids. Of course, depending on the seal model, the spring may come in different shapes. Cone-shaped springs come in different shapes and materials depending on the type of fiber and springs. But this component is indispensible in all of them.

Face seal

It is mounted on the shaft and is always rotating with it. Depending on its application, this seal can be made of carbon or, in most cases, of silicon carbide. A more resistant material called tungsten is also used to make this part.

Mechanical seals can be divided into several classes:

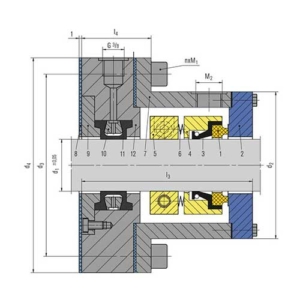

– Split seal

One of the disadvantages of Cartridge seal was that when the seal becomes defective, the whole set needs to be dismantled and replaced. This drawback gave manufacturers an incentive to produce a seal that obviates the need for dismantling the whole system in cases where the seal needs to be replaced. Although split seals are not ubiquitous yet, they will definitely be among the most extensively used seals in the future.

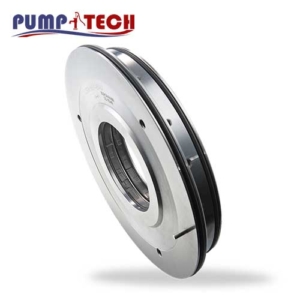

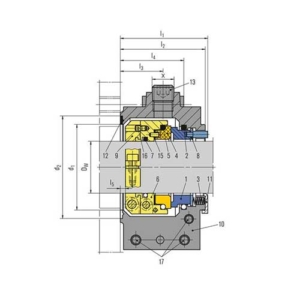

Cartridge seals

Cartridge seals consist of specific components that are mounted on the seal in factory, and this obviates the need for further adjustments. In order to use this seal, one just needs to install it on the system. Although the cartridge seal is much easier to install compared to other types of seals (Burgmann mechanical seal), installation manual should still be used to ensure proper installation.

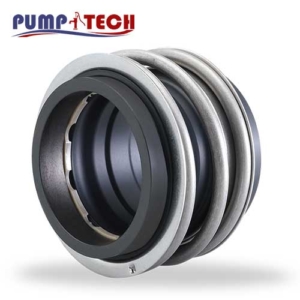

Double seal

This type of seal is used in cases where the operating pressure is high and a single seal cannot prevent leakage.

The Burgmann double seal consists of a second seal that is fitted to the first fiber-spring seal in back-to-back, Face to face or in series configurations in order to help it withstand liquid pressure and prevent liquid leakage.