Features mechanical seal sh300

- Robust seal design – suitable for demanding light hydrocarbon applications

- Compact cartridge seal for small seal chambers

- Single unpressurized seal with a high pressure-non contacting containment seal

- Stationary spring loaded unit

- Balanced primary seal faces in materials with high thermal conductivity and strength

- Multi-point injection of the flush fluid optional

- Seal faces can be equipped with lubrication enhancing grooves and/or DiamondFace technology

Advantages mechanical seal sh300

- High Performance seal for single and multi fluid type pipeline services with variable pressures and speeds

- Low amount of heat generation, hence minimal temperature rise in the seal faces

- Suitable for flashing and non-flashing light hydrocarbons, even with low vapor pressure margins

- Seal faces have soft torque transmission

- Seal faces are shrouded in steel collars so that they cannot break apart in pieces in an emergency case

- Resistant to alignment issues between the pump case and shaft because of stationary springs

- Containment seal is rated for full dynamic pressure of primary seal, i.e. high degree of safety and environmental protection

- Seal face materials are resistant to solids in the pumped fluid

Operating range mechanical seal sh300

- Shaft diameter:

d1* = 50 … 150 mm (1.97″ … 5.91″) - Pressure: p1 = 100 bar (1,450 PSI),

Static: up to 150 bar (2,175 PSI),

Dynamic: up to 100 bar (1,450 PSI) - Temperature: t = -20 … +100 °C (-4 … 212 °F)

- Sliding velocity: vg = 50 m/s (164 ft/s)

- Axial movement: ±1 mm

Materials mechanical seal sh300

- Seal face:

Silicon impregnated carbon (Q3), DiamondFace - Stationary seat: Silicon carbide (Q2), DiamondFace

- Secondary seals: FKM (V), FFKM (K)

- Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), Duplex (G1), Super Duplex (G4), Titan (T2), Hastelloy® C-4 (M)

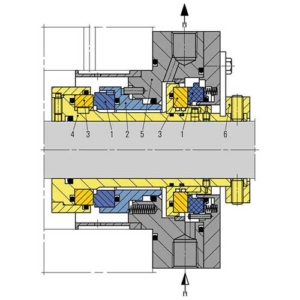

| Item | Description |

| 1 | Seal face |

| 2 | Face housing |

| 3 | Seat |

| 4 | Shaft sleeve |

| 5 | Housing |

| 6 | Set ring |

Recommended applications seal sh300

- Pipeline systems

- Tank farms / storage tanks

- Petrochemical industry

- Refining technology

- Oil & gas production