Features mechanical seal rotechseal

- Gas-lubricated

- Uni- or bi-directional

- Ready-to-fit cartridge unit

- Available for all seal arrangements: single, double, tandem

- Based on proven DGS or PDGS design

- Separation seals as labyrinths, carbon rings or CobaSeal optional

Advantages mechanical seal rotechseal

- “Smart Labyrinth”

- DiamondFace-coating

- Self-cleaning 3D gas grooves

- Soft torque transmission

- Debris resistant dynamic sealing element

- Leakage optimization

Operating range mechanical seal rotechseal

- Shaft diameter:

d = up to 410 mm (16.14″) - Pressure:

p = up to 450 bar (6,525 PSI) and more - Design-temperature:

t = -200 °C … +230 °C (-328 °F … +446 °F) - Sliding velocity:

vg = up to 227 m/s (744 ft/s)

Project specific special designs possible

Materials mechanical seal rotechseal

- Seal face: Silicon carbide with DLC- or DiamondFace-coating

- Seat: Silicon carbide with DLC- or DiamondFace-coating

- Secondary seals: PTFE or FKM

- Metal parts: 1.4006, 1.4313-QT650, 1.4418, 1.4542, Inconel® or other stainless steels

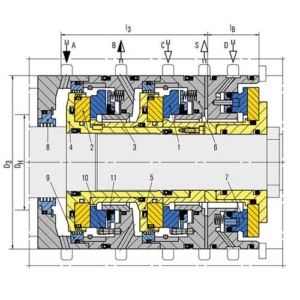

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary seal gas supply |

| S | Secondary vent |

| D | Separation gas supply |

| Pos. | Benennung |

| 1 | Seal face, stationary |

| Feature option: primary seal face with DiamondFace-coating | |

| 2 | Seat, rotating |

| Feature option: primary seat with DiamondFace-coating | |

| 3 | Thrust ring |

| 4 | Shaft sleeve |

| 5 | Adapter sleeve |

| 6 | Housing (size matched to installation space) |

| 7 | Separation seal (CobaSeal) |

| 8 | Labyrinth |

| 9 | Feature option: “smart labyrinth” |

| 10 | Feature option: “soft torque” |

| 11 | Feature option: debris resistant dynamic sealing element |

Recommended applications seal rotechseal Burgmann

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Applications with upstream gas treatment (glycol)

- Hydrocarbon gas

- Ammonia

- Nitrogen

All types of compressors