Features mechanical seal cse

- Non-contacting bushing seal

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Equipped with Espey carbon rings type WKA400

Advantages mechanical seal cse

- Low leakage

- Slow roll capability

- Insensitive to dry nitrogen

Operating range mechanical seal cse

- Shaft diameter:

38 … 390 mm (1,50″ … 15,35″) - Design pressure:

p = … 10 bar (145 PSI)

Operating pressure:

p = 0.07 bar (1.02 PSI) - Temperature:

t = -20 °C … +200 °C (-4 °F … +392 °F) - Sliding velocity:

vg = 0 … 200 m/s (0 … 656 ft/s) - Dew point: No limitation

Materials mechanical seal cse

- Seal face: Carbon graphite impregnated

- Secondary seals: FKM

- Shaft sleeve: Stainless steel, TC-coated

- Metal parts: 1.4006 or other stainless steels

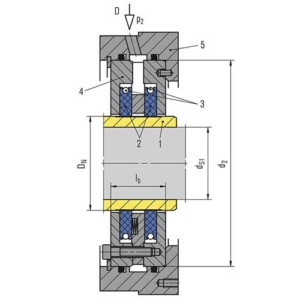

| Item | Description |

| 1 | Shaft sleeve |

| 2 | Segmented carbon ring |

| 3 | Garter spring |

| 4 | Housing of the standardized sub-cartridge |

| 5 | Housing (size matched to installation space) |

| D | Separation gas |

Recommended applications seal cse Burgmann

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Nitrogen

- Air

- Centrifugal compressors

- Turbo expanders

- Screw compressors

- Blowers