Features mechanical seal Splitex

- Fully split single seal, 2 x 2 segments, pre-assembled

- Semi-cartridge

- Balanced

- Stationary springs

- Bi-directional

- External pressurization

- Built-in flushing connections

- Installation and wear control

Advantages mechanical seal splitex

- Reduced repair and downtime: 2 x 2 pre-assembled design speeds up and simplifies installation installation because pump does not have to be disassembled.

- Long service life: precise pre-alignment because of pre-assembled segments. Stationary springs which are protected from the product prevent clogging.

- Greater flexibility during installation: no modification necessary because the seal is located outside of the stuffing box.

- Shaft protection: uniform torque transmission via clamping ring prevents damage caused by set screws.

- Dependable operation: mechanical decoupling of clamping ring (torque transmission) avoids distortion of the seat.

- Simple monitoring of the seal during operation because of mechanical wear indicator on the seal face.

- Low leakage: elimination of secondary seals eliminates leakage paths between split components.

- High tolerance to shaft deflections ensured by stationary design and elastic seat mounting (gasket).

Operating range mechanical seal splitex

- splitexShaft diameter:

d1 = 50 … 150 mm (1.940″ … 6.000″) - Pressure: p1 = 10 bar (145 PSI)

- Temperature:

t = -40 … +150 °C (- 40 … + 300 °F),

above 80 °C (175 °F) flush is recommended - Sliding velocity: vg = 10 m/s (33 ft/s)

- Axial movement: ±1.5 mm (1/16″)

- Radial movement: ±0.8 mm (1/32″)

Materials mechanical seal splitex

- Seal face: Carbon graphite antimoniny impregnated (A), Silicon carbide (Q6)

- Seat: Silicon carbide (Q6)

- Secondary seals: FKM (V), EPDM (E), NBR (P)

- Springs: CrNiMo steel (G)

- Metal parts: CrNiMo steel (G)

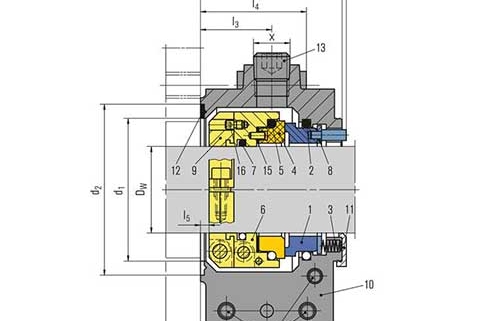

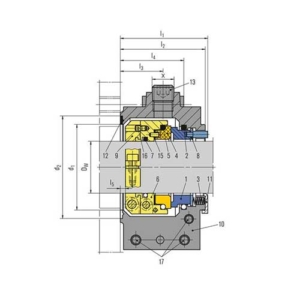

| Item | Description |

| 1 | Seal face |

| 2, 5, 7 | O-Ring |

| 3 | Spring |

| 4 | Seat |

| 6 | Driver |

| 8 | Thrust ring |

| 9 | Clamp collar |

| 10 | Housing |

| 11 | Assembly fixture |

| 12, 15 | Gasket |

| 13 | Head screw plug |

| 14 | Mounting plate |

| 16 | Set screw |

| 17 | Socket head screw |

Recommended applications seal splitex

- Process industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- Pulp and paper industry

- Centrifugal pumps

- Agitators

- Displacement pumps

- Conveying pulp with stock pumps

- Conveying timber to refiners with pumping screws

- Circulation of pulp-and-water mixtures in storage vessels

- Pump stations for waste water treatment

- Cooling water pumps for energy generation