Features mechanical seal shpv / shfv

- Cartridge design

- Single seal

- Balanced

- Dependent of direction of rotation

- Integrated pumping device

- Stationary spring loaded unit

- Multiple springs

- Shrink-fitted seal face

Advantages mechanical seal shpv / shfv

- Deformation-optimized seal for highest pressure levels

- Economical due to standardized inner components

- High flexibility due to adaptation of the connection parts to the pump seal chamber

- Optimum heat dissipation due to integrated pumping device and optimized seat design

- Insensitive to shaft deflections due to stationary design

- Pre-assembled unit for quick and easy installation

- Only small number of components

Operating range seal shpv / shfv

- Shaft diameter:

d1* = 40 … 250 mm (1.57″ … 9.84″) - Pressure: p1 = 150 bar (2,175 PSI)

- Temperature: t = +350 °C (+662 °F)

- Sliding velocity: vg = 60 m/s (197 ft/s)

- Axial movement: ± 3 mm

Materials seal shpv / shfv

- Seal face: Carbon graphite antimony impregranted (A)

- Seat: Silicon carbide (Q)

- Secondary seals: EPDM (E), FFKM (K)

- Springs: CrNiMo steel (G)

- Metal parts: CrNiMo steel (G)

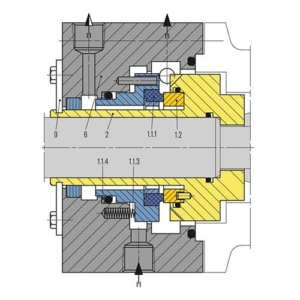

| Item | Description |

| 1.1.1 | Seal face pressure-stabilized |

| 1.1.3 | Spring |

| 1.1.4 | Back-up ring |

| 1.2 | Seat |

| 2 | Seat housing with pumping screw (F) or pumping ring (P) |

| 6 | Cover |

| 9 | Assembly fixture |

Recommended applications seal shpv / shfv

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Power plant technology

- Boiler feed water

- Boiler circulation pumps