Features mechanical seal mg9

- For plain shafts

- Single and dual seal

- Elastomer bellows rotating

- Balanced

- Independent of direction of rotation

- No torsion on bellows and spring

- Conical or cylindrical spring

- Metric and inch sizes available

- Special seat dimensions available

- US Patent No. 6.220.601

Advantages mechanical seal mg9

- Fits into any installation space due to smallest outer seal diameter

- Important material approvals available

- Individual installation length can be achieved

High flexibility due to extended selection of materials - Universal application (standardization)

Operating range mechanical seal mg9

- Shaft diameter:

d1 = 10 … 100 mm (0.375″ … 4″) - Pressure: p1 = 12 bar (174 PSI),

vacuum up to 0.5 bar (7.25 PSI),

up to 1 bar (14.5 PSI) with seat locking - Temperature:

t = -20 °C … +140 °C (-4 °F … +284 °F) - Sliding velocity: vg = 10 m/s (33 ft/s)

- Axial movement: ±0.5 mm

Materials mechanical seal mg9

- Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1)

- Seat: Silicon carbide (Q1, Q2), Aluminium oxide (V)

- Elastomer: NBR (P), EPDM (E), FKM (V), HNBR (X4)

- Metal parts: CrNiMo steel (G)

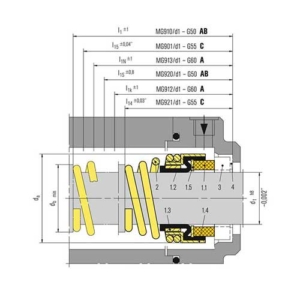

| Item | Part no. to DIN 24250 | Description |

| 1.1 | 472 | Seal face |

| 1.2 | 481 | Bellows |

| 1.3 | 485 | Driver collar |

| 1.4 | 484.1 | “L” ring (spring collar) |

| 1.5 | 474 | Washer |

| 2 | 477 | Spring |

| 3 | 475 | Seat |

| 4 | 412 | Rubber cup |

Recommended applications seal mg9

- Water and waste water technology

- Pulp and paper industry

- Chemical industry

- Cooling fluids

- Media with low solids content

- Pressure oils for bio diesel fuels

- Circulating pumps

- Submersible pumps

- Multi-stage pumps (non-drive side)

- Water and waste water pumps

- Oil applications