Features mechanical seal unitex

- Single cartridge seal

- Elastomer bellows

- Unbalanced

- Independent of direction of rotation

- Rotating spring

- Bellows and spring free from torsion

- Metric and inch sizes available

Advantages mechanical seal unitex

- Straightforward and easy installation

- Fits into any installation space due to smallest outer diameter

- Important material certifications available

- Universal application opportunities (standardization)

- No modifications of the pump’s installation chamber necessary

- Economical cartridge solution

- Comes with flush connection acc. to API 682, Plan 11 for seal chamber cleaning and cooling

Operating range mechanical seal unitex

- Shaft diameter:

dN = 25 … 75 mm (1″ … 2.625″) - Pressure: p1 = 12 bar (174 PSI)

- Temperature:

t = -20 °C … 140 °C (-4 °F … 284 °F) - Sliding velocity: vg = 10 m/s (33 ft/s)

- Axial movement: ±0.5 mm

Materials mechanical seal unitex

- Seal face: Carbon graphite resin impregnated (B), Silicon carbide (Q1)

- Seat: Silicon carbide (Q1)

- Secondary seals: FKM (V), EPDM (E)

- Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

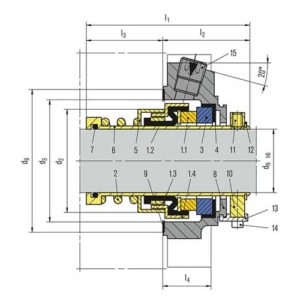

| Item | Description |

| 1 | Bellows unit |

| 1.1 | Seal face |

| 1.2 | Bellows |

| 1.3 | Drive collar |

| 1.4 | L-ring (spring collar) |

| 2 | Spring |

| 3 | Seat (G60) |

| 4 | O-Ring or corner sleeve |

| 5 | Spacer ring |

| 6 | Shaft sleeve |

| 7 | O-ring |

| 8 | Cover |

| 9 | Gasket |

| 10 | Drive collar |

| 11 | Set screw |

| 12 | Snap ring |

| 13 | Assembly fixture |

| 14 | Socket head screw |

| 15 | Screw plug |

Recommended applications seal unitex

- Chemical industry

- Pulp and paper industry

- Water and waste water technology

- Sewage water

- Cold and hot water

- Cooling fluids

- Beverages

- Diluted lyes and acids

- Suspensions with low solids content

- Circulating pumps

- Water and waste water pumps

- Production of pressure oils for bio diesel fuels