Features mechanical seal agsr

- For top, bottom and side entry drives

- Double seal

- Balanced

- Stationary springs on product side

- Independent of direction of rotation

- Gas-lubricated

- Cartridge unit

Advantages mechanical seal agsr

- Ready-to-fit and factory-tested unit

- Rotating seat at product side

- Torque transmission by clamping ring for large axial movements

- Non-contacting operation

- No friction on the seal faces, no heat generated at the seal or in the medium

- Sterile design available

- ATEX certification on request

Operating range mechanical seal agsr

Shaft diameter:

d1 = 20 … 200 mm (0.8″ … 7.9″)Pressure:

p1 = Vakuum … 6 bar (87 PSI),

Δp = min. 3 bar (44 PSI),

p3 = max. 9 bar (131 PSI)Temperature:

t1 = -20 °C … +200 °C

(-4 °F … +392 °F)Sliding velocity: vg = 0 … 5 m/s (0 … 16 ft/s)*

* Higher velocities on request

Materials mechanical seal agsr

- Seal faces and seats: Silicon carbide, FDA conform

- Secondary seals and metallic parts acc. to application and customers’ requirement.

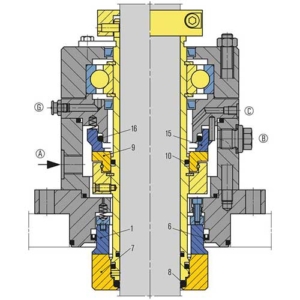

| Item | Description |

| 1, 15 | Seal face |

| 6 | Sealing ring |

| 7, 9 | Seat |

| 8, 10, 16 | O-Ring |

Recommended applications seal agsr Burgmann

- Chemical industry

- Food and beverage industry

- Pharmaceutical industry

- Mixers

- Dryers

- Special rotating equipment

Recommended piping plans

GSS4015/A400-D0,

GSS4016/A250-D1 or

GSS4016/A350-D1.