Features mechanical seal mdgs

- Gas-lubricated

- Bi-directional

- Compact, radial design

- Ready-to-fit cartridge unit, also available as a component seal

- Single, double, tandem seal and tandem with intermediate labyrinth available

Advantages mechanical seal mdgs

- Wear-free and contact-free operation

- Self-cleaning 3D gas grooves

- High gas film stiffness

- Fits into small spaces (e.g. process gas screw compressors)

- Available in various materials for optimized chemical resistance

- Proven, reliable and economical solution

Operating range mechanical seal mdgs

- Shaft diameter:

d1 = 48 … 200 mm (1.89″ … 7.87″) - Pressure:

p = 0 … 50 bar (0 … 725 PSI) - Temperature:

t = -20 °C … +200 °C

(-4 °F … +392 °F) - Sliding velocity:

vg = 0.6 … 200 m/s (2 … 656 ft/s)

Materials mechanical seal mdgs

- Seal face: Carbon graphite

- Seat: Ductile stainless steel with DM-TiN coating

- Secondary seals: FKM

- Metal parts: 1.4006 or other stainless steels.

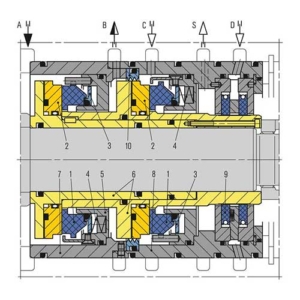

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary gas seal supply |

| S | Secondary vent |

| D | Separation gas supply |

| Item | Description |

| 1 | Seal face, stationary |

| 2 | Seat, rotating |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Adapter |

| 6 | Shaft sleeve, intermediate sleeve |

| 7, 8 | Housing (size matched to installation space) |

| 9 | Carbon ring separation seal (CSE) |

| 10 | Intermediate labyrinth |

Recommended applications seal mdgs Burgmann

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Hydrocarbon gas

- Nitrogen

- Air

- Centrifugal compressors

- Dry process gas screw compressors

- Blowers