Features ed560

- Dual seal

- Good chemical resistance and ability to handle solids

- In-house manufactured sliding parts

Advantages mechanical seal ed560

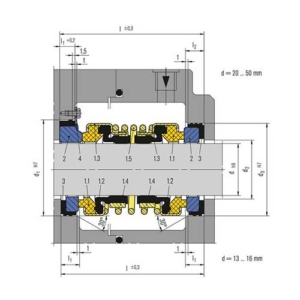

The ED560 is a dual seal in a back-to-back arrangement with an EA560 base. Therefore, the seal combines the advantages of the EA560 with the advantages of a dual seal.

Operating range seal ed560

- Shaft diameter:

d1 = 13 … 50 mm (0.51″ … 1.96″) - Pressure:

p1 = d ≤19 mm: 2 bar (29 PSI),

d ≥ 20 mm: 3 bar (44 PSI),

vacuum … 0.1 bar (1.45 PSI) - Temperature:

t = -20 °C … +70 °C (-4 °F … 158 °F) - Sliding velocity: vg = 5 m/s (16 ft/s)

- Axial movement: ±1.0 mm

Materials mechanical seal ed560

- Seal face: Carbon graphite resin impregnated (B), Silicon carbide (Q1, Q2)

- Seat: Aluminium oxide (V), Silicon carbide (Q1, Q2)

- Elastomer: NBR (P)

- Metal parts: CrNi steel (F)

| Item | Description |

| 1.1 | Seal face |

| 1.2 | Bellows |

| 1.3 | Spring collar |

| 1.4 | Drive collar |

| 1.5 | Spring |

| 2 | Seat |

| 3 | Corner sleeve |

| 4 | Washer |

Recommended applications seal ed560

- Water and waste water technology

- Chemical industry

- Process industry

- Water and waste water

- Glycols

- Oils

- Industrial pumps/equipment

- Submersible pumps

- Engine pumps

- Circulating pumps