Features eh700

- Single seal

- Stationary spring-loaded unit enables

- peration in high-range loads area

- Balanced

- In-house manufactured carbon seal faces

Advantages mechanical seal eh700

The seal for stationary applications. The EH700 is based on a unique stationary spring loaded unit that enables the seal to operate under high speed and high pressure. An additional advantage of the seal is the balanced design, which ensures good sealing performance in high-load conditions.

Operating range mechanical seal eh700

- Shaft diameter: d1 = 15 … 35 mm

- Pressure: p1 = 15 bar (218 PSI),

vacuum up to 0.1 bar - Temperature:

t = -20 °C … +100 °C (-4 °F … +212 °F) - Sliding velocity: vg = 10 m/s (33 ft/s)

- Axial movement: ±1.0 mm

Materials seal eh700

- Seal face: Carbon graphite resin impregnated (B)

- Seat: Aluminium oxide (V, V1), Silicon carbide (Q1, Q2)

- Secondary seals: NBR (P), FKM (V)

- Metal parts: CrNi steel (F)

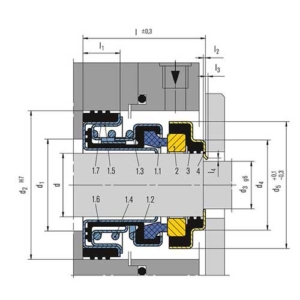

| Item | Description |

| 1.1 | Seal face |

| 1.2 | Bellows |

| 1.3 | Spring collar |

| 1.4 | Spring |

| 1.5 | Spring holder |

| 1.6 | Cartridge |

| 1.7 | Seat ring |

| 2 | Seat |

| 3 | Corner sleeve |

| 4 | Case |

Recommended applications seal eh700 burgmann

- Water and waste water technology

- Food and beverage industry

- Water and waste water

- Glycols

- Industrial pumps

- Engine pumps

- Skyscraper water supply pumps