Features mechanical seal seccolip461

- For top entry drives, on request for side and bottom entry drives

- For glass-lined vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

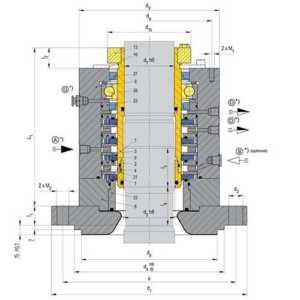

Cartridge unit

Advantages mechanical seal seccolip461

- Available as a ready-to-mount cartridge for quick and easy installation

- Ready-to-fit and factory-tested units

- Safe and environmentally compatible technology

- The glass-lined flange does not have to be replaced – an adaptation is possible

- No monitoring necessary

- No cost-intensive supply system necessary

- Low maintenance requirements

- No additional roller bearing necessary, but optionally available

- Sealing element made of bright chemically highly resistant PTFE compound

- ATEX certification available on request

- Customized adjustments possible

Operating range mechanical seal seccolip461

- Shaft diameter (on stock): d1 = 40 … 125 mm (1.57″ … 4.92″)

- Special shaft diameters between 25 mm and 200 mm possible (0.98″ … 7.87″)

- Pressure: p1 = vacuum … 6 bar (87 PSI)

- Temperature: -30 °C … +200 °C (-22 °F … +392 °F)

- Sliding velocity: vg = 0 … 2 m/s (0 … 6 ft/s)

- Axial movement: ±3.0 mm

- Radial movement: 1.0 mm (up to 3 mm on request)

For applications beyond this range, please inquire.

Materials mechanical seal seccolip461

- Lip sealing element: bright chemically highly resistant PTFE-compound

- Secondary seals: FKM (V)

- Adapter: AL-Oxid

- Metallic parts: 316L /1.4404

| Item | Description |

| 1 | Lip seal |

| 2 | Inset |

| 3 | Disc |

| 4 | Insert ring |

| 6 | O-Ring |

| 7 | Shaft sleeve |

| 8 | Flange |

| 9 | Housing |

| 13 | Shrink disc |

| 16 | Setting device |

| 23 | Spacer ring |

| 27 | Lip seal |

| 28 | Sliding bearing |

Recommended applications seal seccolip461 Burgmann

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Non-toxic media

- Agitators

- Mixers

- Reactors