Features mechanical seal ma290 / ma291

- Cartridge

- Balanced

- Independent of direction of rotation

- Stationary multiple springs

- Springs and pin located on the atmospheric side

Advantages mechanical seal ma290 / ma291

- Extremely short length design –

the total length including the seal cover is less than 50 mm - Easy installing on the pumps without modifying the stuffing box

- Excellent followability due to no influence from run-out, squareness or vibration of the shaft

- Mounted outside the stuffing box for providing excellent air cooling performance

- Un-wetted springs and knock pins for protecting from lockout by liquid

Operating range seal ma290 / ma291

MA290:

- Pressure: p = … 20 bar (290 PSI)

- Temperature:

t = -20 °C …160 °C (-4 °F … 320 °F) (oil),

0 °C … 60 °C (32 °F … 140 °F) (water) - Sliding velocity:

vg = max. 20 m/s (66 ft/s) - Viscosity: 0.5 Pa·s

Solids content: 0.3 %

MA291:

- Pressure: p = … 16 bar (232 PSI)

- Temperature:

t = -20 °C …160 °C (-4 °F … 320 °F) (oil),

0 °C … 60 °C (32 °F … 140 °F) (water) - Sliding velocity: vg = max. 20 m/s (66 ft/s)

- Viscosity: 3 Pa·s

Solids content: 10 %

Materials seal ma290 / ma291

- Seal face (MA290): High density carbon graphite

- Seal face (MA291): Silicon carbide (Q1)

- Seat (MA290/291): Silicon carbide (Q1)

- Metal parts: CrNiMo steel (G)

- Secondary seals: FKM (V)

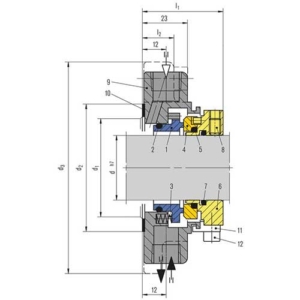

| Item | Description |

| 1 | Seal face |

| 2, 5, 7 | O-Ring |

| 3 | Spring |

| 4 | Seat |

| 6 | Drive collar |

| 8 | Set screw |

| 9 | Seal cover |

| 10 | Gasket |

| 11 | Assembly fixture |

| 12 | HSH cap screw |

Recommended applications seal ma290 / ma291

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Pulp and paper industry

- Water and waste water technology

- Food and beverage industry

- Universally applicable

- Centrifugal pumps

- Eccentric screw pumps

- Process pumps