Features mechanical seal rigiseal

- Modular design

- As upgrade of MAN centrifugal compressors or for new projects

- Availabe as single, double, or tandem seal

- Gas-lubricated

- Uni- or bi-directional

- Ready-to-install unit

- Optionally with separation seal such as labyrinths, carbon rings or EagleBurgmann CobaSeal

Advantages mechanical seal rigiseal

he RigiSeal is the efficient sealing solution when the supply gas is particularly contaminated (e.g., by particles/liquids). Due to the modular design principle, the seal can be adapted on a case-by-case basis for existing machines as well as for new projects. For this purpose, the respective seal features are defined according to the prevailing operating conditions and/or the result of the failure analysis.

Operating range mechanical seal rigiseal

- Shaft diameter:

d = up to 410 mm (16.14″) - Pressure:

p = up to 450 bar (6,525 PSI) and more - Design-temperature:

t = -200 °C … +230 °C (-328 °F … +446 °F) - Sliding velocity:

vg = up to 227 m/s (744 ft/s)

Project specific special designs possible

Materials mechanical seal rigiseal

- Seal face: Silicon carbide with DLC- or DiamondFace-coating

- Seat: Silicon carbide with DLC- or DiamondFace-coating

- Secondary seals: PTFE or FKM

- Metal parts: 1.4006, 1.4313-QT650, 1.4418, 1.4542, Inconel® or other stainless steels

Other materials on request

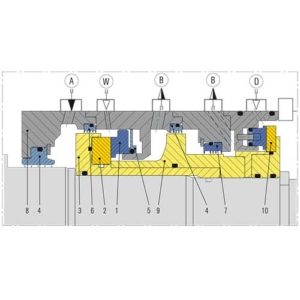

| Item | Description |

| 1 | Seal face, stationary | Option: Primary seal face with DiamondFace coating |

| 2 | Seat, rotating | Option: Primary seat with DiamondFace coating |

| 3 | Shaft sleeve |

| 4 | Labyrinth |

| 5 | Trust ring |

| 6 | Option: “Smart labyrinth” |

| 7 | Option: Labyrinth as back-up seal (PTFE labyrinth) |

| 8 | Housing (size matched to installation space) |

| 9 | Adapter Sleeve |

| 10 | Separation seal | Option: CobaSeal |

Recommended applications seal rigiseal Burgmann

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Applications with upstream gas treatment (glycol)

- Hydrocarbon gas

- Ammonia

- Nitrogen

- Air