Features

- Single seal

- Available for standard (Cartex-ASPN)

- and big bore (Cartex-ABPN) seal

- chambers

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals with flush (-ASPN, -ABPN)

- and with quench combined with lip seal (-ASQN, -ABQN) or throttle ring (-ASTN, -ABTN)

Advantages

- Ideal for use in ANSI process pumps

- Universal applicable for packings conversions, retrofits or original equipment

- Seal for standardizations

- No dimensional modification of the seal chamber necessary, small radial installation height

- No damage of the shaft by dynamically loaded O-Ring

- Extended service life

- Installation faults are avoided, cost-effective

- No damage caused by dirt entered during assembly

- Straightforward and easy installation due to pre-assembled unit (reduced down-times)

Operating range

Cartex-ASPN, – ABPN, -ASTN, -ABTN, -ASQN, -ABQN

Shaft diameter: d1 = 1.000″ … 3.750″

Other sizes on request

Temperature:

t= -40 °C … 220 °C (-40 °F … 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination Q1Q1 or U2Q1

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement:

±1.0 mm, d1 ≥75 mm ±1.5 mm

Materials

Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perflourocarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G)

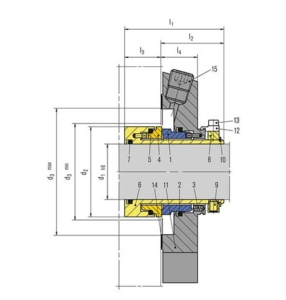

| Item | Description |

| 1 | Seal face |

| 2, 5, 7 | O-Ring |

| 3 | Spring |

| 4 | Seat |

| 6 | Shaft sleeve |

| 8 | Drive collar |

| 9 | Set screw |

| 10 | Snap ring |

| 11 | Cover |

| 12 | Assembly fixture (remove after intallation) |

| 13 | Screw |

| 14 | Gasket |

| 15 | Screw plug |

| 16 | Lip seal (-QN), throttle ring (-TN) |

Recommended applications

- Process industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Food and beverage industry

- Universally applicable

- ANSI process pumps