Features mechanical seal cobaseal

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Self cleaning 3D gas grooves

- Aerostatic and aerodynamic lift-off

Advantages mechanical seal cobaseal

- Extremely low leakage

- Double arranged (co-axial) dry gas seal with just one pair of seal faces

- Insensitive to oil contamination due to its special design

- Wear-free, non-contacting operation in all conditions

- Insensitive to radial vibrations due to axial sealing gap

- Slow-roll or turning operation capable (static lift-off)

- No limits regarding dew point of separation gas (silicon carbide instead of carbon)

- Lower N2 consumption than any other system

- N2 can be switched off during standstill – the gap will close and still provide the best oil sealing performance

- Best in class oil sealing by extremely small sealing gap and sling effect of rotating ring

Operating range mechanical seal cobaseal

- Shaft diameter:

29.5 … 355 mm (1.16″ … 13.97″) - Design pressure (mechanical integrity):

p = 0 … 70 bar (0 … 1000 PSI) - Normal operating pressure:

p = 2.7 bar (39.16 PSI) - Temperature:

t = -20 °C … +200 °C (-4 °F … +392 °F) - Sliding velocity:

vg = 0 … 150 m/s (0 … 492 ft/s)

Dew point: No limitation

Materials mechanical seal cobaseal

- Seal face: Silicon carbide*

- Seat: Ductile stainless steel*

- Shaft sleeve: Stainless steel TC-coated

- Secondary seals: FKM

- Metal parts: 1.4006

* With special EagleBurgmann high performance iDLC (in situ Diamond-Like-Carbon) coating

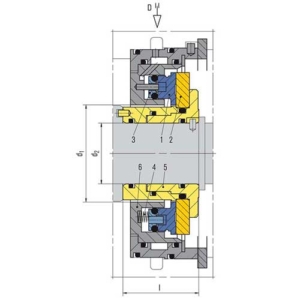

| Item | Description |

| 1 | Seal face, stationary |

| 2 | Seat, rotating |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Shaft sleeve and seat retainer |

| 6 | Housing (size matched to installation space) |

| D | Separation gas |

Recommended applications seal cobaseal Burgmann

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Nitrogen

- Air

- Centrifugal compressors

- Blowers