Features mechanical seal mflct8

- For unstepped shafts

- Single seal

- Balanced

- Independent of direction of rotation

- Metal bellows rotating

Advantages mechanical seal mflct8

- For extreme cold temperature ranges

- No dynamically loaded O-Ring

- Self cleaning effect

- Short installation length possible

- Pumping screw for highly viscous media available (dependant on direction of rotation).

Operating range mechanical seal mflct8

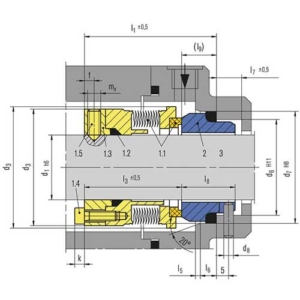

- Shaft diameter:

d1 = 24 … 150 mm (0.94″ … 6“) - Externally pressurized:

p1 = … 25 bar (363 PSI) - Internally pressurized:

p1 = 10 bar (145 PSI ),

stationary seat lock necessary. - Temperature:

t = -100 °C … +100 °C (-148 °F … 212) °F - Sliding velocity: vg = 20 m/s (66 ft/s)

Materials mechanical seal mflct8

- Seal face: Carbon graphite antimony impregnated (A), Silicon carbide (Q12)

- Seat: Silicon carbide (Q1)

- Bellows: Inconel® 718 hardened (M6), Hastelloy® C-276 (M5)

- Metal parts: CrNiMo steel (G), Hastelloy® C-4 (M)

| Item | Part no. DIN 24250 | Description |

| 1.1 | 472/481 | Seal face with bellows unit |

| 1.2 | 410 | Sealing ring |

| 1.3 | 474 | Drive collar |

| 1.4 | Socket head screw | |

| 1.5 | 904 | Set screw |

| 2 | 475 | Seat |

| 3 | 412 | Sealing ring |

Recommended applications Seal MFLCT8

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Cold media

- Highly viscous media

- Pumps

- Special rotating equipment