Features mechanical seal cobaDGS

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

Advantages mechanical seal cobaDGS

- No methane-/ process gas emissions

- Supplied with clean nitrogen (no dew point and dirt problems)

- Robust

- Offers higher safety than a double seal

- Upgrade-possibility of existing single, double and tandem seals

- No modification of the compressor necessary

- Efficient alternative to hermetically sealed systems

- For compressors with gas- and steam turbines, as well as with electric drive

Operating range mechanical seal cobaDGS

- Shaft diameter:

d = 25 … 350 mm (0.99“… 13.78“) - Pressure:

p = from vacuum up to 160 bar (2,321 PSI) - Design temperature:

t = -46 °C … +230 °C

(-51 °F … +446 °F) - Sliding velocitiy:

vg = up to 140 m/s (459 ft/s)

Materials mechanical seal cobaDGS

- Stationary seal face: Silicon carbide with DLC-coating, DiamondFace-coating optional

- Rotating seal face (Seat): Silicon carbide with DLC-coating, DiamondFace-coating optional

- Secondary seals: FKM or other elastomers, depending on product gas composition

- Metal parts: 1.4006 or other stainless steels

Other materials on request.

Dimensions on request

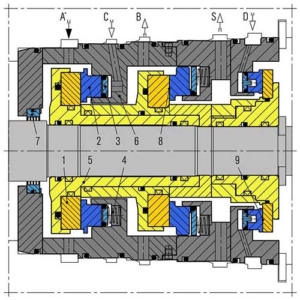

| Item | Description |

| 1 | (Seat) Rotating seal face |

| 2 | (Seal face) Stationary seal face |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Shaft sleeve |

| 6 | Housing |

| 7 | Labyrinth |

| 8 | DGS as seal on atmoshere side |

| 9 | CobaSeal as separation seal |

Recommended applications seal cobaDGS Burgmann

- Pipelines

- Gas storages

- Oil and gas industry

- Chemical industry

- Power plants

- Centrifugal compressors

- Turbo expander

- Turbines

- Pumps

- Blower