Features mechanical seal ehj

- For unstepped shafts

- Single seal

- Balanced

- Independent of direction of rotation

- Encapsulated rotating spring

Advantages seal ehj

- Especially designed for solids containing and highly viscous media

- Springs are protected from the product

- Rugged and reliable design

- No damage of the shaft by dynamically loaded O-Ring

- Universal application

- Variants for sterile operation available

- Increased axial movement

- DiamondFace coating possible

- Spring protection and vibration damping

- Insensitive to temperature changes

100 % compatible to HJ9… for l1k

Operating range mechanical seal ehj

- Shaft diameter:

d1 = 18 … 100 mm (0.71″ … 4″) - Pressure:

p1*) = vacuum … 40 bar (vacuum … 580 PSI) - Temperature:

t = -50 °C … +220 °C (-58 °F … +430 °F) - Sliding velocity: vg = 20 m/s (66 ft/s)

- Axial movement:

d1 = 18 … 25 mm: ±0,5 mm

d1 = 28 … 55 mm: ±0,8 mm

d1 = 60 … 100 mm: ±1,0 mm

* An integral stationary seat lock is not needed within the permissible low pressure range. For prolonged operation under vacuum it is necessary to arrange for quenching on the atmospheric side.

Materials seal ehj

- Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (eSIC-Q7)

- Seat G6: Silicon carbide (eSIC-Q7)

- Secondary seals: E, EL, V, V16, K, KL, P

- Springs: CrNiMo steel (G)

- Face housing: CrNiMo steel (G)

- Driver: Duplex (G1)

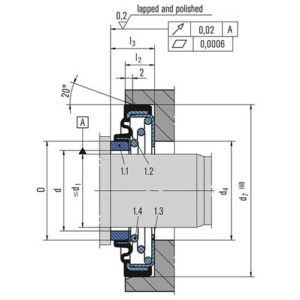

| Item | Description |

| 1 | Seal face |

| 2 | Face housing |

| 3, 5, 7, 9, 12 | O-Ring |

| 4 | Square pin |

| 6 | Spring |

| 8 | Driver |

| 10 | Set screw |

| 11 | Seat |

Recommended applications seal ehj

- Water and waste water technology

- Drinking water

- Chemical industry

- Oil and Gas

- Petrochemical industry

- Refining technology

- Pulp and paper industry

- Power plant technology

- Mining industry

- Metal production and processing

- Special applications (Cement, …)

- Shipping Industry