Features mechanical seal gso-dn

- Seat rotating

- Stationary springs

- Double seal

- Balanced

- Standard version with V-grooves, U-grooves optional (independent of direction of rotation)

- Gas-lubricated

Advantages mechanical seal gso-dn

- Contact free operation

- Face-to-face

Cartridge unit - Does not open in the event of buffer pressure failure

- Self closing at pressure reversal

- No additional complex components to dissipate frictional heat

Operating range mechanical seal gso-dn

- Shaft diameter:

d1 = 30 … 75 mm (1,125″ … 2,625″)

(other dimensions on request) - Product pressure:

p1 = max. 22 bar (319 PSI),

(dependent on shaft diameter and sliding materials) - Barrier pressure: p3 = max. 25 bar (362 PSI),

- Differential pressure: Δp= min. 3 bar (44 PSI)

- Temperature:

t = -20 °C … +170 °C (-4 °F … +338 °F)

(dependent on resistance of O-Rings) - Sliding velocity: vg = 16 m/s (52 ft/s),

with special design max. 25 m/s (82 ft/s) - Axial movement: ±0.2 mm

Materials mechanical seal gso-dn

- Seal faces: Carbon graphite (A)

- Seat: Silicon carbide (Q1, Q2)

- Secondary seals:

FKM (V), EPDM (E), FFKM (K) - Springs: Hastelloy® C-4 (M)

- Metal parts:

CrNiMo steel (G), Hastelloy® C-4 (M)

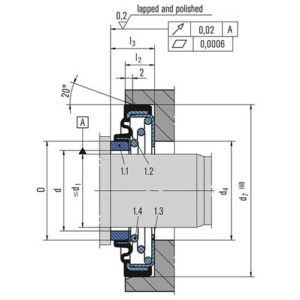

| Item | Description |

| 1, 2 | Seal face |

| 3, 4, 8, 10, 13 | O-Ring |

| 5, 6 | Spring |

| 7 | Seat |

| 9 | Shaft sleeve |

| 11 | Flange |

| 12 | Gasket |

| 14 | Cover |

| 15, 22, 25 | Countersunk screw |

| 16 | Retaining ring |

| 17 | Pin |

| 18 | Ring |

| 19 | Set ring |

| 20 | Set screw |

| 21 | Pumping ring |

| 23 | V-Seal |

| 24 | Assembly fixture |

Recommended applications seal gso-dn

- Chemical industry

- Refining technology

- Gases and liquids

- Media which require high purity

- Environmental harmful media

- Blowers

- Fans

- Pumps