Features

- Dual seal

- Balanced

- Independent of direction of rotation

- Independent of pressure direction

Advantages

- Robust and easy to install design

- Springs protected from the product

- No metal parts on the product side

- Simple conversion of gland packings

Operating range

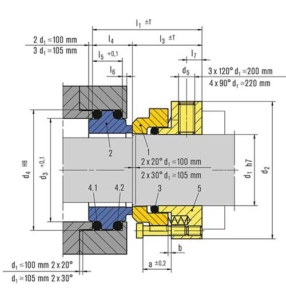

- Shaft diameter:

- d1 = 20 … 300 mm (0.79″ … 11.81″)

- Pressure: p1 = 16 bar (232 PSI)

- Temperature:

- t = -40 °C … 220 °C ( -40 °F … 428° F)

- Sliding velocity: vg = 20 m/s (66 ft/s)

Materials

- Seal face:

- Silicon Carbide (Q2), CrMo cast steel (S)

- Seat: Carbon graphite resin

- impregnated (B), Silicon carbide (Q2)

- Secondary seals:

- EPDM (E), NBR (P), FKM (V), FFKM

- (K), coated (M)

- Springs: CrNiMo steel (G)

- Metal parts: CrNiMo steel (G)

| Item | Description |

| 1.1, 1.2 | Seal ring |

| 2.1, 2.2 | Mating ring |

| 3.1, 3.2, 4.1, 4.2, 4.3 | O-Ring |

| 5.1 | Clamping ring |

| 5.2 | Screw |

| 5.3 | Set screw |

| 5.4 | Spring |

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Building services industry

- Food and beverage industry

- Shipbuilding

- Sugar industry

- Metal production and processing