Features mechanical seal h10 / h8

- Single seal

- Balanced

- Independent of direction of rotation

- Stationary multiple springs

Advantages mechanical seal h10 / h8

- Insensitive to solids in the medium

- Very short axial installation length (analog lip seals) combined with high pressure capability

- No damage of the shaft by dynamically loaded O-Ring

- Due to the stationary design insensitive to shaft misalignements

- Compact ready-to-install unit

Operating range seal h10 / h8

- Shaft Diameter:

d1 = 15 … 100 mm (0.6″ … 3.9″) - Pressure: p1 = 25 bar (363 PSI)

- Temperature:

t = -40 … +180 °C (-40 °F … 356 °F) - Sliding velocity: vg = 35 m/s (115 ft/s)

Materials mechanical seal h10 / h8

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B)

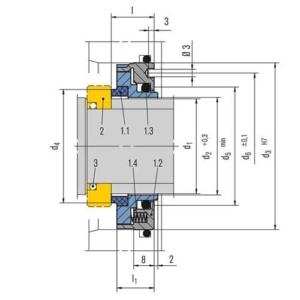

| Item | Part no. DIN 24250 | Description |

| 1.1 | 472 | Seal face |

| 473 | Seal face housing | |

| 1.2 | 485 | Drive collar |

| 1.3 | O-Ring | |

| 1.4 | 477 | Spring |

| 2 | 475 | Rotating seat*) |

| 3 | 412.2 | O-Ring |

Recommended applications seal h10 / h8

- Process industry

- Chemical industry

- Water and waste water technology

- Lube oils

- Roller seal

- Bearing seal

- All seal chambers with a very short axial installation length