Features mechanical seal hr

- Single seal

- Balanced

- Independent of direction of rotation

- Multiple springs stationary

- Seat rotating

- Seat arranged directly behind the impeller

- Spring protection sleeve

- Variant with cylindrical spring and acc. EN 12756 (HRZ1) available

- Variant as cartridge with/without guide sleeve for application with/without quench (HR2, HR3)

- Dual seal as cartridge unit (HRKS-D) available

Advantages mechanical seal hr

- Especially for application in solids containing media without external flush or internal product circulation. Solids content 40 % (single seal) and 60 % (double seal)

- Operation under vacuum without seat locking possible

- Pumping screw for increased circulation available

- Springs are protected from product and leakage

Operating range mechanical seal hr

- Shaft diameter: d1 = … 65 mm (2.56″)

- Pressure: p1 = 0.3 bar (4.35 PSI)

- Temperature:

t = -20 °C … 100 °C (-4 °F … 212 °F) - Sliding velocity: vg = 10 m/s (33 ft/s)

Materials mechanical seal hr

- Seal face: Carbon graphite resin impregnated (B)

- Secondary seals: NBR (P)

- Springs: CrNi steel (F)

- Metal parts: CrNi steel (F)

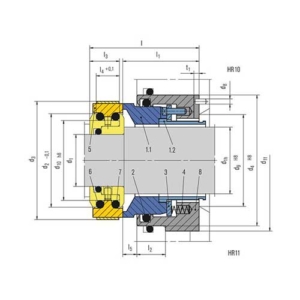

| Item | Part no. DIN 24250 | Description |

| 1.1 | 472 | Seal face |

| 1.2 | 520 | Sleeve |

| 2 | 412.1 | O-Ring |

| 3 | 474 | Thrust ring |

| 4 | 477 | Spring |

| 5 | 475 | Seat (G11) |

| 6 | 412.2 | O-Ring |

| 7 | 412.3 | O-Ring |

| 8 | 441 | Housing |

Recommended applications seal hr

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Building services industry

- Food and beverage industry

- Shipbuilding

- Sugar industry

- Metal production and processing