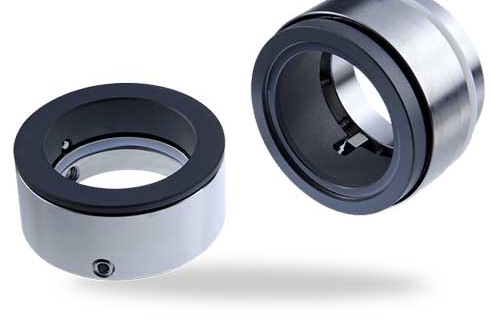

Features mechanical seal hrn

- Single seal

- Balanced

- Independent of direction of rotation

- Stationary springs

- Dual seals in tandem as well as back-to-back arrangements (also in combination with H10 seal)

Advantages mechanical seal hrn

- Safe operation (no fractures) because of seal face locking by square pin

- Spring unit averted from the product so no sticking and clogging of the springs

- Suitable for pressure reversals

- Operation in vacuum without additional seat locking possible

- No damage of the shaft by a dynamically loaded O-Ring

- Small installation sizes

- Best suitable for conversions, no adaptations of the pump

- Insensitive to solid containing and abrasive media

- Advantages of a balanced seal even with plain shafts

- Insensitive to shaft movements because of the stationary design

Operating range mechanical seal hrn

- Shaft diameter:

d = 18 … 100 mm (0.71″ … 3.94″) - Pressure: p1*) = 25 bar (363 PSI)

- Temperature:

t = -40 °C … +220 °C (-40 °F … 428 °F) - Sliding velocity: vg = 20 m/s (66 ft/s)

- Axial movement: ±1.0 mm

* Additional seat locking is not needed in vacuum operation. For operation under vacuum it is necessary to arrange for quenching on the atmosphere side.

Materials mechanical seal hrn

- Shaft diameter:

d = 18 … 100 mm (0.71″ … 3.94″) - Pressure: p1*) = 25 bar (363 PSI)

- Temperature:

t = -40 °C … +220 °C (-40 °F … 428 °F) - Sliding velocity: vg = 20 m/s (66 ft/s)

- Axial movement: ±1.0 mm

* Additional seat locking is not needed in vacuum operation. For operation under vacuum it is necessary to arrange for quenching on the atmosphere side.

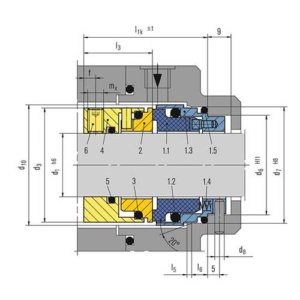

| Item | Part no. to DIN 24250 | Description |

| 1.1 | 472 | Seal face |

| 1.2 | 412.1 | O-Ring |

| 1.3 | 485 | Retainer |

| 1.4 | 477 | Spring |

| 1.5 | 412.2 | O-Ring |

| 2 | 475 | Seat |

| 3 | 412.3 | O-Ring |

| 4 | 485 | Drive collar |

| 5 | 412.4 | O-Ring |

| 6 | 904 | Set screw |

Recommended applications seal hrn

- Water and waste water technology

- Refining technology

- Dirty, abrasive and solid containing media

Fugitive hydrocarbons (no API seal!) - Sticky and stringy media

- Chemical standard pumps

- Sewage pumps