Features mechanical seal lp-d

- Integrated seal for Sulzer A pumps

- Dual seal, balanced

- Semi cartridge unit

- Independent of direction of rotation

- Double pressure balanced

- Internal barrier fluid circulation

- Static springs on both sides

- No dynamic O-Ring on shaft

- Rugged design

- Shrink-fitted seal faces

- Seal faces have a large clearance to the shaft

Wear part cost minimized - Optimized design for Non-Flow use

Advantages mechanical seal lp-d

- Individually integrated to equipment for the best sealing result

- Straightforward and easy installation

- Static springs on both face sides reduces influence of misalignment

- No damage of the shaft by dynamically loaded O-Rings

- Extended service life due to rugged design

- No brittle parts in contact with torque transmission pins

- Seal faces protected by strong steel parts and a large radial clearance

Operating range mechanical seal lp-d

- Temperature:

t = -20 °C … +140 °C (-4 °F … +284 °F)

(180 °C (356 °F) with Kalrez® elastomers) - Pressure:

p1 … 25 bar (363 PSI), p3 <12 bar (174 PSI) - Sliding velocity: vg … 20 m/s (66 ft/s)

Stock content: <8 %

Non-flow operation:

- Temperature:

t = +5 °C … +100 °C (+41 °F … +212 °F) - Pressure:

p1 max. 10 bar (145 PSI), p3 > p1 - Sliding velocity: vg <10 m/s (33 ft/s)

Materials mechanical seal lp-d

- Seal face: Silicon carbide (Q12), Carbon (A)

- Secondary seals: FKM (V), EPDM (E), FFKM (K)

- Metal parts: CrNiMo steel (G),

Grade 5A (4T), SMO 654 (4U)

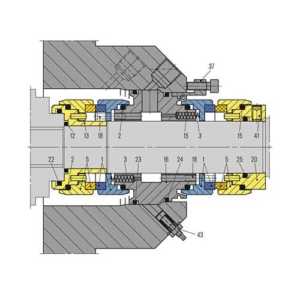

| Item | Designation |

| 1 | Seal face |

| 5 | Seat |

| 13 | Sleeve |

| 16 | Housing |

| 18 | Pin |

| 37 | Locking fixture |

| 2, 12, 15, 22, 23, 24, 25 | O-Ring |

| 43 | Plug |

Recommended applications seal LP-D

- Pulp and paper industry

- Chemical industry

- Clean, abrasive or corrosive liquids

- Stocks of various kind

- Applications where crystallization is a problem

- Sulzer Ahlstar A (MS11) centrifugal pumps