Features mechanical seal h74-d

- For stepped shafts

- Dual seal

- Balanced

- Rotating multiple springs

- Independent of direction of rotation

- Seal concept based on the H7 range

- Variant with pumping screw available (H74F-D)

Advantages mechanical seal h74-d

- Efficient stock keeping due to easily interchangeable faces

- Extended selection of materials

- Flexibility in torque transmissions

- Insensitive to low solids contents

- EN 12756 (For connection dimensions d1 up to 100 mm (3.94″))

Operating range mechanical seal h74-d

- Shaft diameter:

d1 = 14 … 200 mm (0.55″ … 7.87″) - Pressure:

p1 = 80 bar (1,160 PSI) for d1 = 14 … 100 mm,

p1 = 25 bar (363 PSI) for d1 = 100 … 200 mm,

p1 = 16 bar (232 PSI) for d1 > 200 mm - Temperature:

t = -50 °C … 220 °C (-58 °F … 428 °F) - Sliding velocity: vg = 20 m/s (66 ft/s)

- Axial movement:

d1 up to 100 mm: ± 0.5 mm

d1 from 100 mm: ± 2.0 mm

Materials mechanical seal h74-d

- Seal face: Silicon carbide (Q1, Q2), Carbon graphite antimony impregnated (A), Aluminium oxide (V), Special cast CrMo steel (S)

- Seat G9: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1*, Q2*)

- Secondary seals: EPDM (E), NBR (P), FKM (V), FFKM (K)

Springs: CrNiMo steel (G) - Metal parts: CrNiMo steel (G), Duplex (G1)

* Cannot be combined with seal face made of S

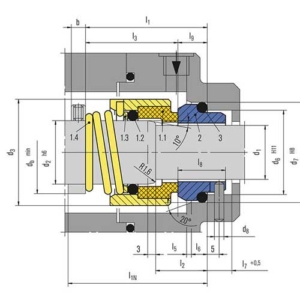

| Item | Part no. to DIN 24250 | Description |

| 1.1 | 472.1 | Seal face |

| 1.2 | 472.2 | Seal face |

| 1.3 | 474 | Thrust ring |

| 1.4 | 485 | Drive collar |

| 1.5 | 477 | Spring |

| 1.6 | 904 | Set screw |

| 1.7 | 412.1 | O-Ring |

| 1.8 | 412.2 | O-Ring |

| 2 | 475.1 | Seat (G9) |

| 3 | 412.3 | O-Ring |

| 4 | 475.2 | Seat (G9) |

| 5 | 412.4 | O-Ring |

Recommended applications seal h74-d

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Power plant technology

- Pulp and paper industry

- Low solids content and low abrasive media

- Toxic and hazardous media

- Media with poor lubrication properties

Adhesives - Chemical standard pumps