Features mechanical seal h75vn

- Single seal

- Cartridge unit

- Design acc. to API 682 / ISO 21049

- Category 2 and 3, Type A, Arrangement 1

- Independent of direction of rotation

- Rotating multiple springs

- Integrated pumping device available (H75VP)

Advantages mechanical seal h75vn

- “Low-Emission-Seal” acc. to the American STLE-limits

- Universally applicable both for retrofits or original equipment

- Efficient stock-keeping due to standardized components

- Extended selection of materials

- Extended field of operation in terms of temperature and pressure

- Metal parts also in special materials available

Operating range mechanical seal h75vn

Shaft diameter:

d = 20 … 110 mm (0.79″ … 4.33″)*Pressure: p1 = 40 bar (580 PSI)

Temperature:

t = -40 °C … +220 °C (-40 °F … 428 °F)Sliding velocity: vg = 23 m/s (75 ft/s)

Axial movement: ± 2.0 … 4.0 mm depending on diameter and installation situation

* Other sizes on request

Materials mechanical seal h75vn

- Seal face: Carbon graphite antimony impregnated (A)

- Seat: Silicon carbide (Q1, Q2)

- Secondary seals: EPDM (E), NBR (P), FKM (V), FFKM (K)

- Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G), Duplex (G1), Hastelloy® C-4 (M)

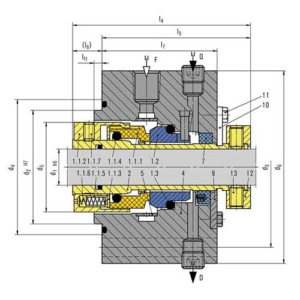

| Item | Description |

| 1.1.1 | Seal face |

| 1.1.2 | Driver |

| 1.1.3 | Thrust ring |

| 1.1.4, 1.3 | O-Ring |

| 1.1.5 | Sleeve |

| 1.1.6 | Spring |

| 1.1.7 | Set screw |

| 1.2 | Seat |

| 2 | Shaft sleeve |

| 4 | Housing |

| 5 | Insert |

| 7 | Throttle ring |

| 9 | Washer |

| 10 | Assembly fixture |

| 11 | Hexagon bolt |

| 12 | Set ring |

| 13 | Set screw |

Recommended applications Seal h75vn

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Power plant technology

- Light hydrocarbons

- Hot water

- API 610 / ISO 13709 pumps

- Process pumps