RMO Main applications

The RMO series are used on trucks and lorries for the handling of liquids in the food industry such as milk, beer and wine.

They can also be used for the handling of AD Blue, drinking water and other liquids.

RMO Design

This pump series is especially produced for installation on lorries and trucks and are constructed on a stainless steel bearing pedestal. They can be equipped with an optional hydraulic or electric motor. Pumps provided with an electric motor can be powered by the batteries of the truck and can be executed in a monobloc design.These perfectly cleanable pumps have stainless steel 316L pump casings constructed in thick cold rolled plate, 100% non-porous and extremely smooth. Some of them have an investment cast casing, resulting in an even more solid design.

RMO benefits pump

- High pump efficiency, low motor power

- Low NPSH values: less risk on cavitation

- Short built-in dimensions, space saving

- Robust design, smooth operation

- Higher capacity

- Low noise level

RMO Description

This pump series is especially produced for installation on lorries and trucks and are constructed on a stainless steel bearing pedestal. They can be equipped with an optional hydraulic or electric motor. Pumps provided with an electric motor can be powered by the batteries of the truck and can be executed in a monobloc design.These perfectly cleanable pumps have stainless steel 316L pump casings constructed in thick cold rolled plate, 100% non-porous and extremely smooth. Some of them have an investment cast casing, resulting in an even more solid design.

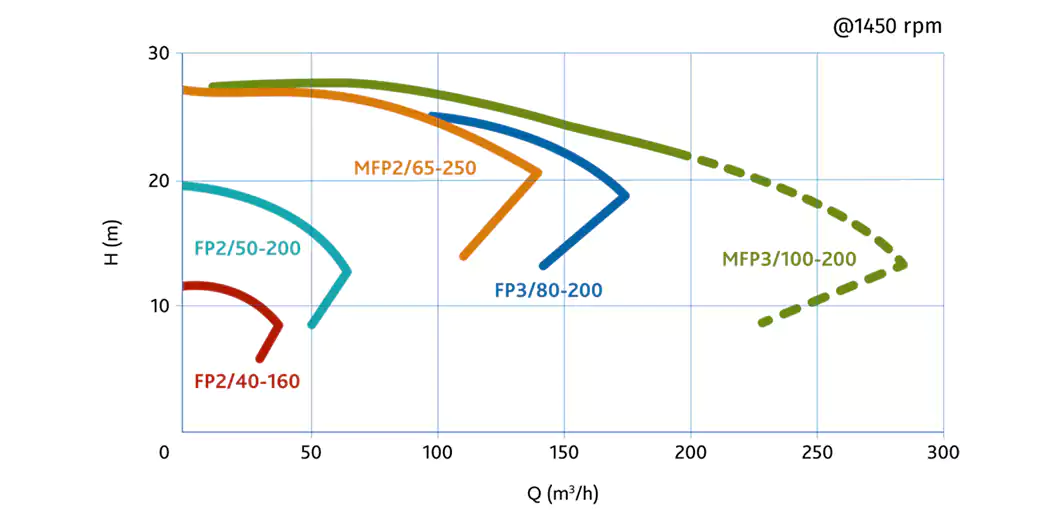

rmo Curve

Overview of technical data rmo

| Max. flow | 250 m3/h |

| Differential head | 30 m wc |

| Max. Inlet pressure | 10 bar |

| Viscosity | 1000 cP |

| Max. temperature | 140 °C |

| Impeller type | Open / closed |

| Max. free passage | 25 mm |

| Speed | Variable |

| Materials wetted parts | 316L or similar |

| Mechanical seal configuration | Single |

| Available material O-ring | EPDM, FKM |

| Connections | Hygienic fittings |

| Surface finish | Hygienic quality, internal welds hand polished + electropolished (casing 0.8 μm – impeller 3.2 μm except for MFP series) |

| Drive | Hydraulic motor or electromotor |

| Certificates | EHEDG. 1935/2004 EC. FDA. USP. MEI. EAC |