GFP Main applications

The multi-phase pump is a combination of a standard centrifugal pump and a liquid ring pump both mounted together on 1 motor and 1 shaft. The centrifugal pump is used for pumping the liquid and brings the main performance of the pump.

When a gas-bubble starts to build up in the eye of the centrifugal impeller, it is evacuated by the liquid ring impeller.

The pump has 1 suction and 2 discharges: a main discharge of the centrifugal pump and a smaller discharge of the liquid ring pump that functions as an air and foam vent. The air/foam vent is typically connected back to the suction vessel.

GFP Design

The multi-phase pump is a combination of a standard centrifugal pump and a liquid ring pump both mounted together on 1 motor and 1 shaft. The centrifugal pump is used for pumping the liquid and brings the main performance of the pump. When a gas-bubble starts to build up in the eye of the centrifugal impeller, it is evacuated by the liquid ring impeller. The pump has 1 suction and 2 discharges: a main discharge of the centrifugal pump and a smaller discharge of the liquid ring pump that functions as an air and foam vent. The air/foam vent is typically connected back to the suction vessel. The GFP multi-phase pump is typically used for foaming liquids and (viscous) liquids containing gas in the food-industry. Offering a solution to liquids that are difficult to pump with standard centrifugal pumps. E.g. starch slurries & proteins

GFP Description

The multi-phase pump is a combination of a standard centrifugal pump and a liquid ring pump both mounted together on 1 motor and 1 shaft. The centrifugal pump is used for pumping the liquid and brings the main performance of the pump. When a gas-bubble starts to build up in the eye of the centrifugal impeller, it is evacuated by the liquid ring impeller. The pump has 1 suction and 2 discharges: a main discharge of the centrifugal pump and a smaller discharge of the liquid ring pump that functions as an air and foam vent. The air/foam vent is typically connected back to the suction vessel. The GFP multi-phase pump is typically used for foaming liquids and (viscous) liquids containing gas in the food-industry. Offering a solution to liquids that are difficult to pump with standard centrifugal pumps. E.g. starch slurries & proteins

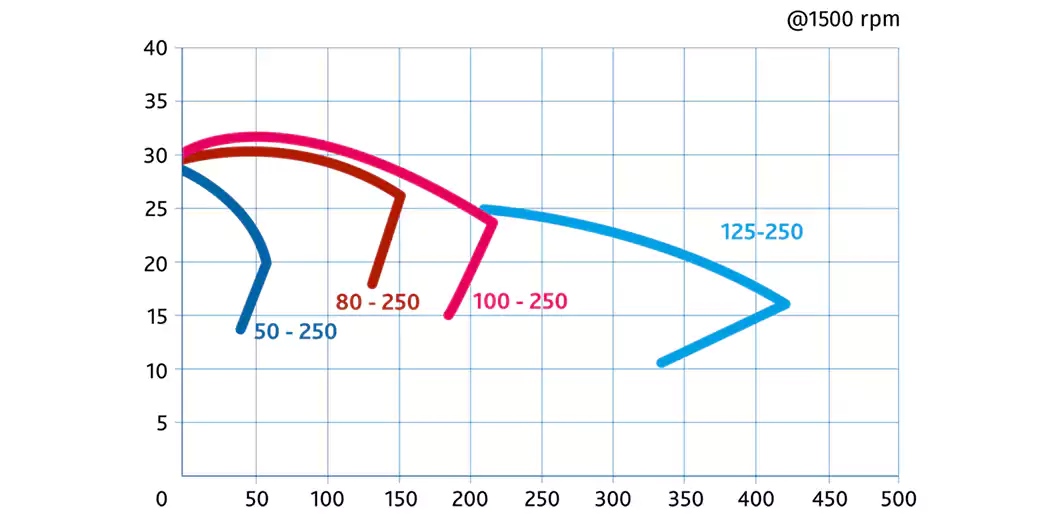

GFP Curve

Overview of technical data GFP

| Max. flow | 400 m3/h |

| Differential head | 30 m wc |

| Max. Inlet pressure | 10 bar |

| Viscosity | 1000 cP |

| Max. temperature | 140 °C |

| Impeller type | Open or closed |

| Max. gas content | 30% |

| Max. drive power | 45 kW |

| Speed | 1800 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single bellow, sterile |

| Available material O-ring | EPDM, FKM, FFKM |

| Connections | EN1092-1 & ANSI flanges. DIN11851. SMS. RJT. Tri-Clamp |

| Surface finish | Electropolished |

| Certificates | FDA. EAC |