MSCP Main applications

This self-priming side channel pump is used in various applications where air must be pumped in against a high back pressure in the discharge line.

The MSCP has exceptional suction power and air handling capacity. This means it can completely empty the suction line, even with foaming and slightly more viscous liquids.

It is often used for unloading trucks and pumping in high silos.

MSCP Design

Both the pump casing, the impellers and the lantern piece with bearing support of this self-priming pump consist of electrolytically polished precision casting in stainless steel 316L. This results in a robust, reliable pump with a very fine surface structure. This self-priming side channel pump is used in various applications where air must be pumped in against a high back pressure in the discharge line. The MSCP has exceptional suction power and air handling capacity. This means it can completely empty the suction line, even with foaming and slightly more viscous liquids. It is often used for unloading trucks and pumping in high silos.

MSCP benefits pump

- Exceptional suction power and air handling capacity thanks to impeller with profiled blades (optional)

- Sucks the suction line completely empty

- Also suitable for foaming liquids and liquids that are slightly more viscous

- Hygienic design

- Electrolytically polished: easy to clean

- Standard engine and mechanical seal are the best guarantee for reasonable spare part prices

MSCP Description

Both the pump casing, the impellers and the lantern piece with bearing support of this self-priming pump consist of electrolytically polished precision casting in stainless steel 316L. This results in a robust, reliable pump with a very fine surface structure. This self-priming side channel pump is used in various applications where air must be pumped in against a high back pressure in the discharge line. The MSCP has exceptional suction power and air handling capacity. This means it can completely empty the suction line, even with foaming and slightly more viscous liquids. It is often used for unloading trucks and pumping in high silos.

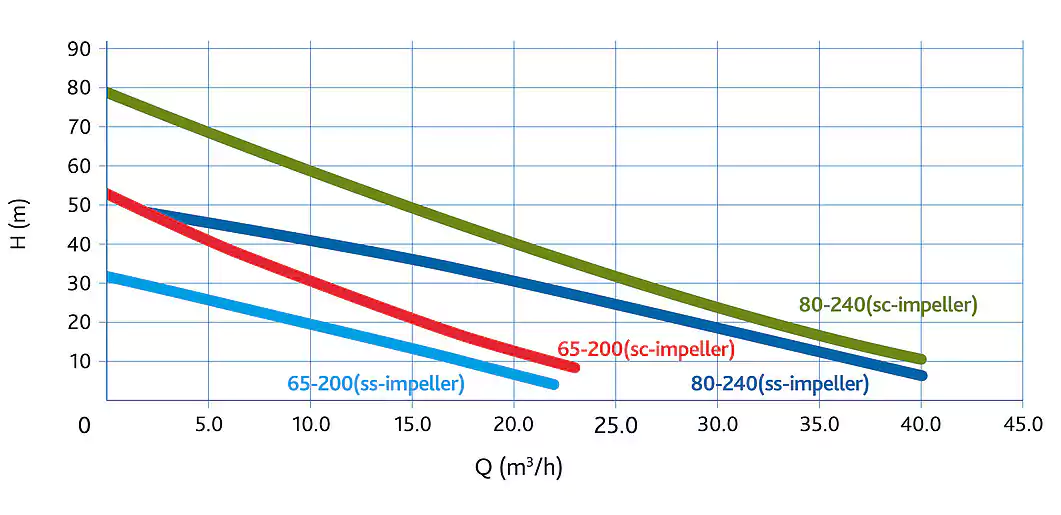

MSCP Curve

Overview of technical data MSCP

| Max. flow | 40 m3/h |

| Differential head | 75 m wc |

| Max. Inlet pressure | 5 bar |

| Viscosity | 300 cP |

| Max. temperature | 140 °C |

| Impeller type | Star impeller with straight or profiled blades |

| Max Airhandling capacity | 50 l/min |

| Max suction depth | 8,5m |

| Max. drive power | 15 kW |

| Speed | 1500/1800 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Diverse types single mechanical seal |

| Available material O-ring | EPDM, FKM, FFKM |

| Connections | DIN11851. SMS. RJT. DIN11864-1. DIN11864-2 |

| Surface finish | Electropolished |

| Certificates | 1935/2004 EC. FDA. EAC. USP |