About Pump dml-dmlf

Cast iron submersible pump with single-channel impeller that allows a free passage up to 76 mm, usable in fixed and mobile installations. Suitable for pumping wastewater with suspended solids

Features

- Possibility to use in fixed and mobile installations

- Single channel impeller

description Pump dml-dmlf

Cast iron submersible pump with single-channel impeller that allows a free passage up to 76 mm, usable in fixed and mobile installations.

The DML – DMLF electric pumps stand out for their sturdiness and resistance, ideal for large applications and heavy-duty use.

For further technical information see the Databook

• Evacuation of civil and industrial wastewater

• Slurry treatment

• Drainage of underwater areas

• General Handling of liquids, including those with solid and/or filamentary substances in suspension

• Emptying of seepage water

• Handling of dirty wastewater (sanitary services) and emptying of cesspits

Overview of technical data dml-dmlf

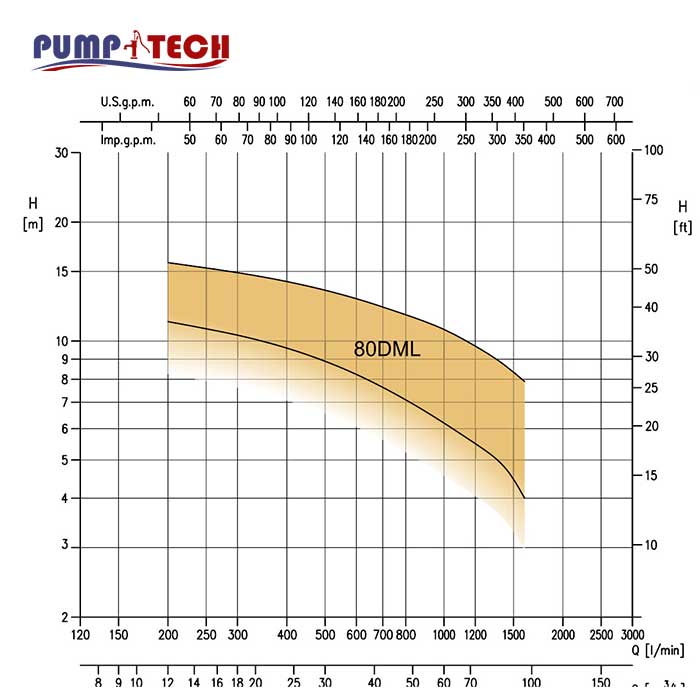

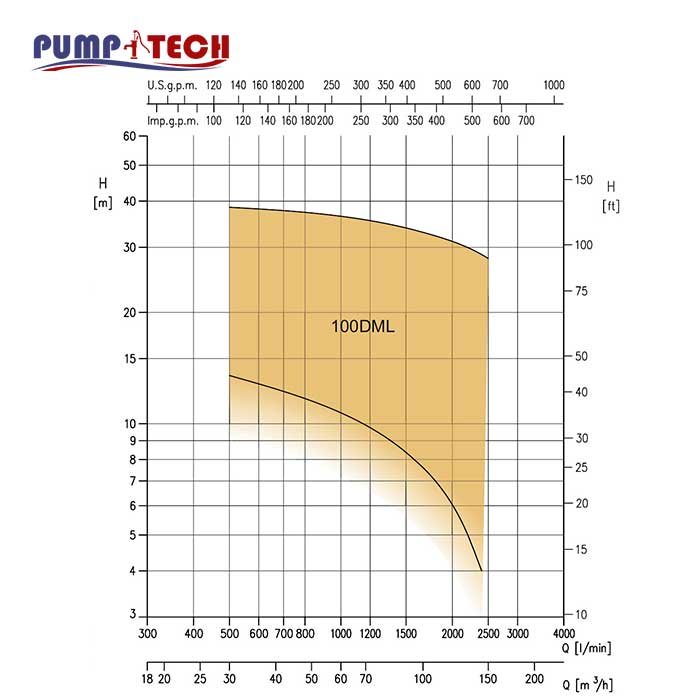

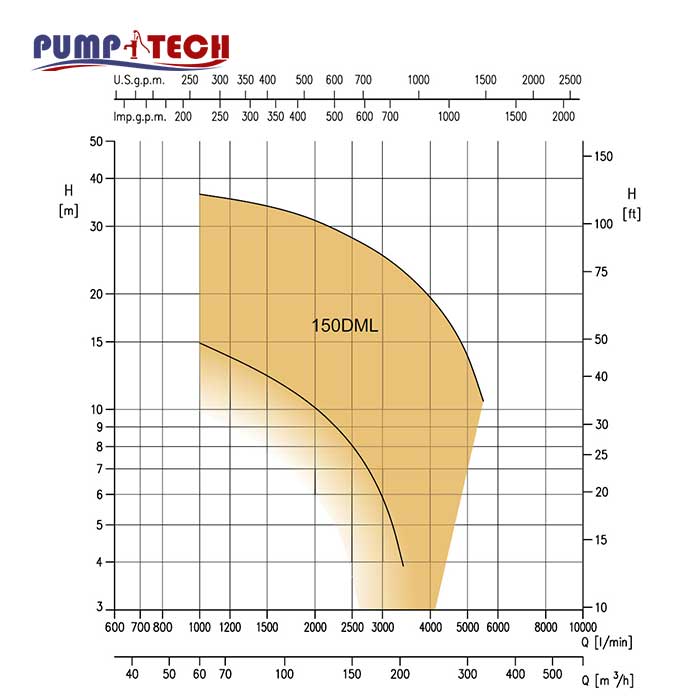

| Flow rate | Up to 330 m³/h (DML) Up to 45 m³/h (DMLF) |

| Total head | Up to 38.5 m (DML) Up to 16.5 m (DMLF) |

| Max. temperature of the liquid | +40°C |

| Poles | 2, 4 |

| Max. solids passage | 76 mm (DML) 30 mm (DMLF 1.4 kW) 40 mm (DMLF) |

| Insulation class | F (DML) H (DMLF) |

| Protection degree | IP68 |

| Voltage | Three-phase 3~380-415V -10+6% (DML 2.2 kW) – DOL Three-phase 3~380-415V ±10% (DML 3.7÷22 kW) – Y/Δ Single-phase 1~230V ±10% (DMLF) |

| Max. immersion | 7 m with 10 m cable |

| Max. length of fibres | 500 mm |

Material Pump dml-dmlf

| Pump body | Cast iron |

| Impeller | Cast iron |

| Shaft | Stainless steel 403 (EN 1.4006) (DML) Stainless steel 420B (EN 1.4028) (DMLF) |

| Mechanical seal | Impeller side: Silicon Carbide/NBR (DML and DMLF) Motor side: Carbon / Ceramic / NBR (DML) |

pump dml-dmlf

Submersible electric pumps with single-channel impeller (DML-DMLF)

Pump body, single-channel impeller, cast iron (bend) elbow.

The shaft is in AISI 403 for DML-DMLV

Mechanical seal:

– SiC/SiC/NBR (pump side) for DML and DMLF

– Carbon/Ceramic/NBR (motor side) for DML and DMLF

– SiC/SiC/NBR (pump side) for DMLV and DMLVF

– Carbon/Ceramic/NBR (motor side) for DMLV and DMLVF

Technical

- Total head from 4 to 38.5 m for DML

from 2.4 to 16.5 m for DMLF

from 1,4 to 41.3 m for DMLV(F) - Capacity from 12 to 330 m3/h for DML

from 7 to 45 m3/h for DMLF

from 12 to 200 m3/h for DMLV(F) - Maximum liquid temperature 40°C

- Maximum solid size passage:

– 76 mm (DML)

– 30 mm (DMLF up to 1,4 kW)

– 40 mm (DMLF)

– 80 ÷ 100 mm (DMLV)

– 30 ÷ 80 mm (DMLVF) - Maximum length of fibrous bodies 400 mm for 80DMLV, 500 mm for 100DMLV and

40 mm for DMLF