About Pump dmlv-dmlvf

Cast iron submersible pump with vortex impeller that facilitates the passage of solids and prevents clogging, usable in fixed and mobile installations. Suitable for pumping wastewater with suspended solids

Features

- Possibility to use in fixed and mobile installations

- Vortex impeller

description Pump dmlv-dmlvf

Cast iron submersible pump with vortex impeller that facilitates the passage of solids and prevents clogging, usable in fixed and mobile installations.

DMLV – DMLVF electric pumps are advanced technical solutions that provide high-level performance, especially in heavy-duty applications.

For further technical information see the Databook

• Soiled liquids

• Civil and industrial wastewater or liquids containing solid and/or filamentary substances in suspension

Overview of technical data dmlv-dmlvf

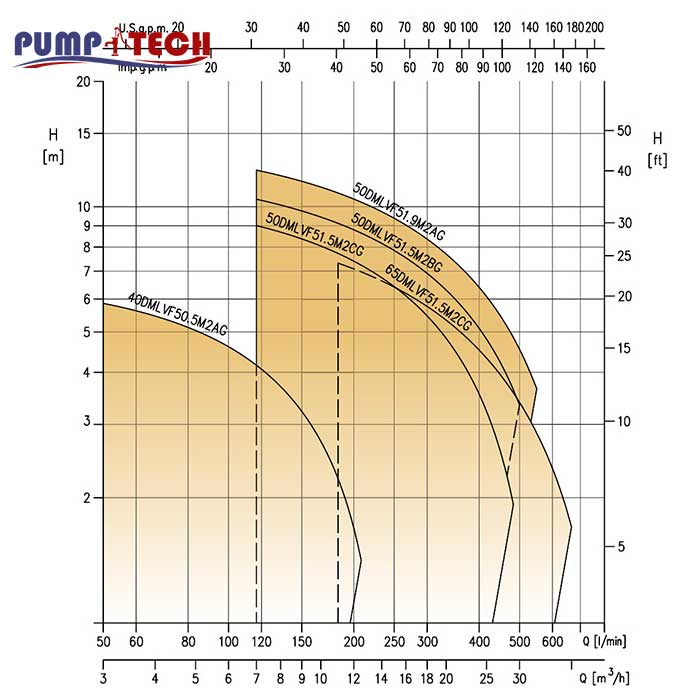

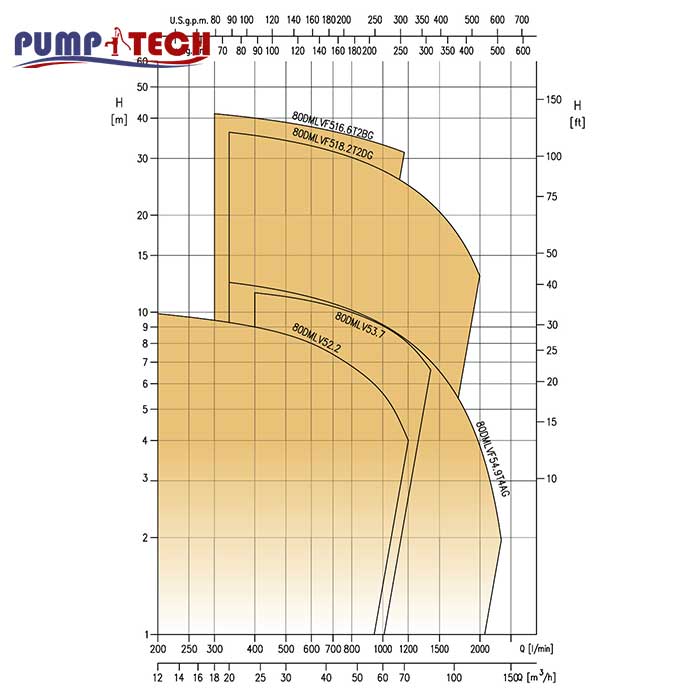

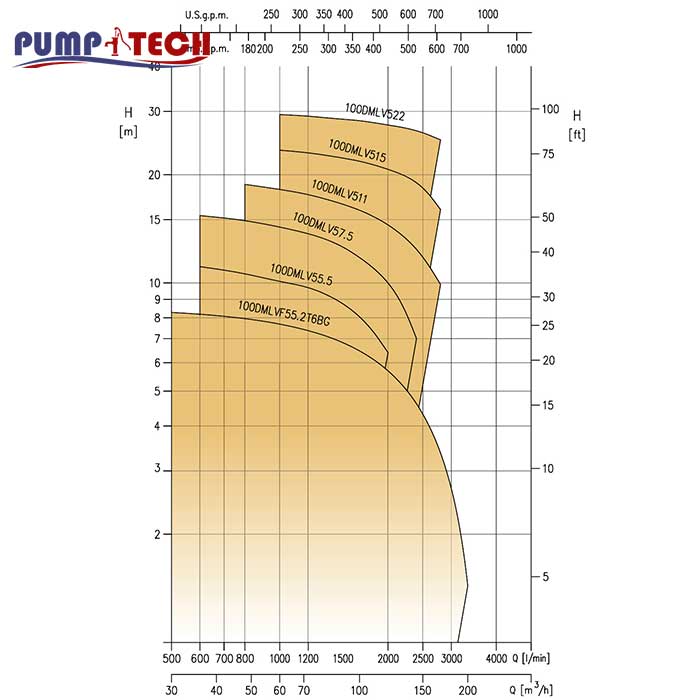

| Flow rate | Up to 168 m³/h (DMLV) Up to 200 m³/h (DMLVF) |

| Total head | Up to 41.3 m (DML) Up to 29.4 m (DMLVF) |

| Max. temperature of the liquid | +40°C |

| Poles | 2, 4 |

| Max. solids passage | 80÷100 mm (DMLV) 30÷80 mm (DMLVF) |

| Insulation class | F (DMLV) H (DMLVF) |

| Protection degree | IP68 |

| Voltage | Three-phase 3~380-415V -10 +6% (DMLV 2.2 kW) – DOL Three-phase 3~380-415V ±10% (DMLV 3.7÷22 kW) – Y/Δ Single-phase 1~230V ±10% (DMLVF) Three-phase 3~400/690V ±10% (DMLVF) |

| Max. immersion | 7 m with 10 m cable |

| Max. length of fibres | 400 mm (80DMLV) 500 mm (100DMLV) |

Material Pump dmlv-dmlvf

| Pump body | Cast iron |

| Impeller | Cast iron |

| Shaft | Stainless steel 403 (EN 1.4006) (DMLV) Stainless steel 420B (EN 1.4028) (DMLVF) |

| Mechanical seal | Impeller side: Silicon carbide/Silicon carbide/NBR Motor side: Carbon/Ceramic/NBR |

pump dmlv-dmlvf

Submersible electric pumps with single-channel impeller (DML-DMLF) or with vortex impeller (DMLV-DMLVF) cast iron, for sewage.

Pump body, single-channel impeller, cast iron (bend) elbow.

The shaft is in AISI 403 for DML-DMLV and in AISI 420B for DMLF-DMLVF.

Mechanical seal:

– SiC/SiC/NBR (pump side) for DML and DMLF

– Carbon/Ceramic/NBR (motor side) for DML and DMLF

– SiC/SiC/NBR (pump side) for DMLV and DMLVF

– Carbon/Ceramic/NBR (motor side) for DMLV and DMLVF

Technical

- Total head from 4 to 38.5 m for DML

from 2.4 to 16.5 m for DMLF

from 1,4 to 41.3 m for DMLV(F) - Capacity from 12 to 330 m3/h for DML

from 7 to 45 m3/h for DMLF

from 12 to 200 m3/h for DMLV(F) - Maximum liquid temperature 40°C

- Maximum solid size passage:

– 30 mm (DMLF up to 1,4 kW)

– 40 mm (DMLF)

– 80 ÷ 100 mm (DMLV)

– 30 ÷ 80 mm (DMLVF) - Maximum length of fibrous bodies 400 mm for 80DMLV, 500 mm for 100DMLV and

40 mm for DMLF