About Pump MATRIX

Multistage horizontal AISI 304 stainless steel centrifugal pump, suitable for drinking water. Available in various versions and models, suitable for many domestic and industrial applications

Features

- Compact dimensions

- Sturdy construction

- Silent

description Pump MATRIX

Multistage horizontal AISI 304 stainless steel centrifugal pump, suitable for drinking water.

Its sturdy construction and compact design allow its installation in various domestic and industrial applications.

For further technical information see the Databook

- Pressure boosters

- Water distribution and treatment

- Heating and air conditioning

- Cooling and chillers

- Irrigation and rainwater harvesting

- Industrial washing

- Industrial installations

Overview of technical data MATRIX

| Flow rate | Up to 27 m³/h |

| Total head | Up to 97 m |

| Max. working pressure | 10 bar |

| Max. temperature of the liquid | 15°C ÷ +85°C for std, H, HS versions -15°C ÷ +110°C for TE version for high temperatures |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump MATRIX

| Pump body | AISI 304 |

| Impeller | AISI 304 |

| Shaft | Stainless steel AISI 304 (EN 1.4301) |

| Mechanical seal | Ceramic/Carbon/EPDM (standard) H = Graphite/Ceramic/FPM HS = Silicon Carbide/Silicon Carbide/FPM |

| Motor support | EN AB-AISi11Cu2(Fe) (precision-cast aluminium) |

pump MATRIX

Horizontal multistage centrifugal electric pumps characterised by a sturdy and compact construction. Available in various versions and models and suitable for many applications: pressure groups, water distribution and treatment, heating and air conditioning, cooling and chiller, irrigation and rainwater recovery, industrial washing and industrial systems.

- Body, impellers, intermediate stages, seal holder disc and shaft (part in contact with the liquid) in AISI 304.

- The standard mechanical seal is in Ceramic/Carbon/EPDM; then there is the possibility of using different types of special seals to reach a temperature range from -15°C to +110°C WRAS-certified for standard models up to 85°C.

- It is possible to combine these pumps with 2 poles, self-ventilated, high efficiency asynchronous motors.

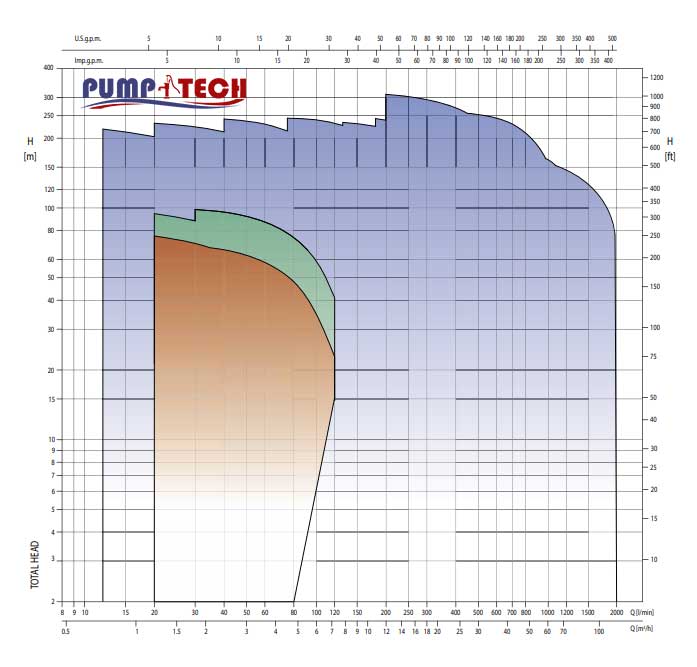

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of = 1 mm2/s (1 cSt)

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

P2 = pump power input (shaft power)

= pump efficiency

NPSH = net positive suction head required by the pump

Technical

- Total head up to 97 m

- Capacity up to 27 m3/h

- IE3 high efficiency motors starting from 0.75 kW

- Maximum liquid temperature

from -15°C to +85°C (standard)

from -15°C to +110°C (TE version for high temperatures)

Q=Capacity | Motor Power | Pump type MATRIX | ||||||||||

130 | 100 | 80 | 60 | 45 | 30 | 20 | 0 | l/min | HP | KW | Three phase | Single phase |

7.8 | 6 | 4.8 | 3.6 | 2.7 | 1.8 | 1.2 | 0 | m/h | ||||

H=Total manometric head in meters | ||||||||||||

– | – | 8.0 | 13.6 | 17.0 | 19.6 | 20.9 | 22.6 |

| 0.6 | 0.45 | 3-2 0.45 | MATRIX 3-2 1.45M |

– | – | 12.0 | 20.4 | 25.5 | 29.3 | 31.4 | 33.9 |

| 0.9 | 0.65 | 3-3 0.65 | MATRIX 3-3 0.65M |

– | – | 16.0 | 27.0 | 34.0 | 39.1 | 42.0 | 45.0 |

| 0.9 | 0.65 | 3-4 0.65 | MATRIX 3-4 0.65M |

– | – | 20.0 | 34.0 | 42.5 | 49.0 | 52.5 | 56.5 |

| 1.0 | 0.75 | 3-5 0.75 | MATRIX 3-5 0.75M |

– | – | 24.0 | 41.0 | 51.0 | 58.5 | 62.5 | 68.0 |

| 1.2 | 0.9 | 3-6 0.9 | MATRIX 3-6 0.9M |

– | – | 28.0 | 47.5 | 59.5 | 68.5 | 73.0 | 79.0 |

| 1.8 | 1.3 | 3-7 1.3 | MATRIX 3-7 1.3M |

– | – | 32.0 | 54.5 | 68.0 | 78.0 | 83.5 | 90.5 |

| 1.8 | 1.3 | 3-8 1.3 | MATRIX 3-8 1.3M |

– | – | 36.0 | 61.0 | 76.5 | 88.0 | 94.0 | 102.0 |

| 2.0 | 1.5 | 3-9 1.5 | MATRIX 3-9 1.5M |

8.8 | 14.7 | 17.4 | 19.3 | 20.5 | 21.5 | – | 23.0 |

| 0.6 | 0.45 | 5-2 0.45 | MATRIX 5-2 0.45M |

13.2 | 22.0 | 26.0 | 29.0 | 30.7 | 32.3 | – | 34.5 |

| 0.9 | 0.65 | 5-3 0.65 | MATRIX 5-3 0.65M |

17.6 | 29.4 | 34.7 | 38.6 | 41.0 | 43.0 | – | 46.0 |

| 1.2 | 0.9 | 5-4 0.9 | MATRIX 5-4 0.9M |

22.0 | 36.7 | 43.5 | 48.5 | 51.0 | 54.0 | – | 57.5 |

| 1.8 | 1.3 | 5-5 1.3 | MATRIX 5-5 1.3M |

26.4 | 44.0 | 52.0 | 58.0 | 61.5 | 64.5 | – | 69.0 |

| 1.8 | 1.3 | 5-6 1.3 | MATRIX 5-6 1.3M |

30.8 | 51.5 | 61.0 | 67.5 | 72.0 | 75.5 | – | 80.5 |

| 2.0 | 1.5 | 5-7 1.5 | MATRIX 5-7 1.5M |

35.2 | 58.5 | 69.5 | 77.0 | 82.0 | 86.0 | – | 92.0 |

| 3.0 | 2.2 | 5-8 2.2 | MATRIX 5-8 2.2M |

39.6 | 66.0 | 78.0 | 87.0 | 92.0 | 97.0 | – | 104.0 |

| 3.0 | 2.2 | 5-9 2.2 | MATRIX 5-9 2.2M |

Q=Capacity | Motor Power | Pump type MATRIX | ||||||||||||||

450 | 400 | 350 | 300 | 250 | 200 | 160 | 130 | 100 | 80 | 60 | 0 | l/min | HP | KW | Three phase | Single phase |

27 | 24 | 21 | 18 | 15 | 12 | 9.6 | 7.8 | 6 | 4.8 | 3.6 | 0 | m/h | ||||

H=Total manometric head in meters | ||||||||||||||||

– | – | – | – | 5.8 | 12.8 | 17.0 | 19.1 | 20.6 | 21.4 | 22.2 | 24.0 |

| 1.0 | 0.75 | 10-2 0.75 | MATRIX 10-2 0.75M |

– | – | – | – | 8.7 | 19.3 | 25.5 | 28.6 | 30.9 | 32.1 | 33.3 | 36.0 |

| 1.8 | 1.3 | 10-3 1.3 | MATRIX 10-3 1.3M |

– | – | – | – | 11.6 | 25.7 | 34.0 | 38.1 | 41.0 | 43.0 | 4.5 | 48.0 |

| 2.0 | 1.5 | 10-4 1.5 | MATRIX 10-4 1.5M |

– | – | – | – | 14.5 | 32.1 | 42.5 | 47.5 | 51.5 | 53.5 | 55.5 | 60.0 |

| 3.0 | 2.2 | 10-5 2.2 | MATRIX 10-5 2.2M |

– | – | – | – | 17.4 | 38.5 | 51.0 | 57.0 | 62.0 | 64.5 | 66.5 | 72.0 |

| 3.0 | 2.2 | 10-6 2.2 | MATRIX 10-6 2.2M |

5.2 | 10.3 | 14.2 | 16.8 | 18.7 | 20.2 | 21.3 | 22.0 | – | – | – | 24.2 |

| 2.0 | 1.5 | 18-2 1.5 | MATRIX 18-2 1.5 |

7.8 | 15.5 | 21.3 | 21.3 | 28.1 | 30.4 | 31.9 | 33.0 | – | – | – | 36.3 |

| 3.0 | 2.2 | 18-3 2.2 | MATRIX 18-3 2.2M |

10.4 | 20.6 | 28.4 | 28.4 | 37.4 | 40.5 | 42.5 | 44.0 | – | – | – | 48.5 |

| 4.0 | 3.0 | 18-4 3 | MATRIX |

13.0 | 25.8 | 35.5 | 35.5 | 47.0 | 50.5 | 53.0 | 55.0 | – | – | – | 60.5 |

| 5.5 | 4 | 18-5 4 | MATRIX |

15.6 | 30.9 | 42.5 | 42.5 | 56.0 | 60.5 | 64.0 | 66.0 | – | – | – | 72.5 |

| 5.5 | 4 | 18-6 4 | MATRIX |