About Pump Compact

Multistage horizontal cast iron centrifugal pump with technopolymer impeller, particularly silent and versatile for many domestic applications.

Features

- Lightweight and easily transportable

- Practical and easy to use

- Silent

description Pump compact

Multistage horizontal cast iron centrifugal pump with technopolymer impeller. Its compact, lightweight, silent and sturdy structure makes it a versatile product for many domestic applications.

For further technical information see the Databook

• Domestic pressurisation

• Pressure boosting in general

• Garden irrigation systems

• Vehicle washing

• Handling of clean water

Overview of technical data compact

| Flow rate | Up to 7.2 m³/h |

| Total head | Up to 79 m |

| Max. working pressure | 10 bar |

| Max. temperature of the liquid | +40°C |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP44 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump compact

| Pump body | Cast iron |

| Impeller | PPE+PS with glass fibres |

| Shaft | Stainless steel 416 (EN 1.4005) |

| Mechanical seal | Ceramic/Carbon/NBR (standard) |

| Motor support | Cast iron |

| Stages | PPE+PS with glass fibres/PTFE |

pump compact

Extremely silent horizontal multistage centrifugal electric pumps. Suitable for pressure increases in general, domestic pressurisation, small garden irrigation, vehicle washing and clean water handling.

• High silence

• The pumps are equipped with 2-pole energy efficient asynchronous motors.

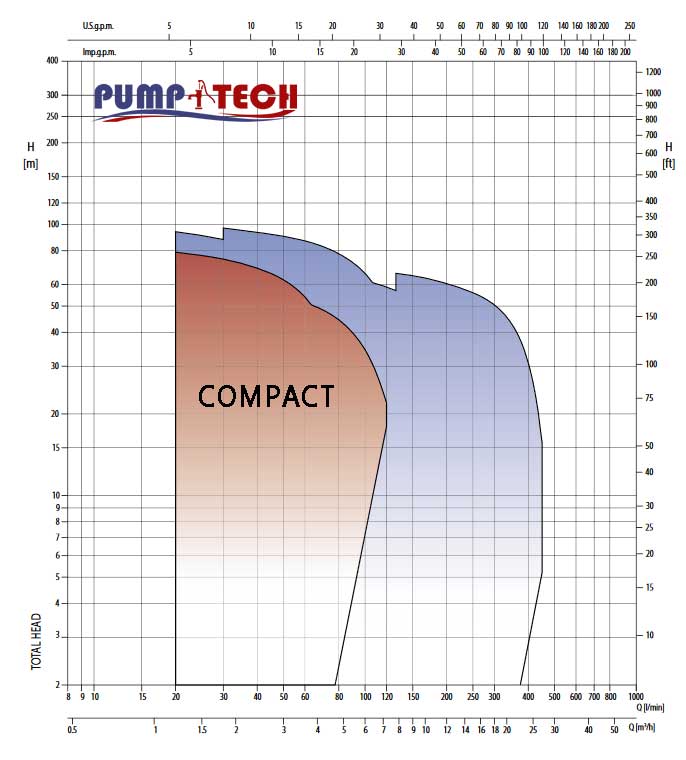

CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of v = 1 mm2/s (1 cSt)

The NPSH curve is an average curve obtained in the same conditions of performance curves.

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

Technical Data

• Total head from 6 to 79 m

• Capacity from 1.2 to 7.2 m3/h

• Maximum operating pressure 10 bar

• Maximum liquid temperature 40°C

• The pump body and the support are in cast iron, the outer jacket is in

AISI 304. The impeller and diffuser are made of PPE + PS reinforced with

glass fibres and PTFE. The shaft is in AISI 416.

• The mechanical seal is in Ceramic/Carbon/NBR

Pump type | KW | Capacitor | Absorbed Current (A) | l/min | Q=Capacity | |||||||||||

Single-phase 230V 50hz | Three-phase 230/400v 50hz | µF | Vc | Single-phase | Three-phase | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 120 | |||

230V | 400V | m/h | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.8 | 6 | 7.2 | ||||||

H=Total Head | ||||||||||||||||

COMPACT AM/4 | COMPACT A/4 | 0.3 | 10 | 450 | 2.5 | 1.9 | 1.1 |

| 21 | 18.7 | 16.7 | 14.4 | 11.9 | 6 | – | – |

COMPACT AM/6 | COMPACT A/6 | 0.44 | 12.5 | 450 | 3.0 | 2.3 | 1.3 |

| 31 | 28.2 | 25.2 | 21.8 | 18 | 9 | – | – |

COMPACT AM/8 | COMPACT A/8 | 0.6 | 14 | 450 | 4.0 | 2.6 | 1.5 |

| 40 | 36.1 | 32 | 27.4 | 22.4 | 10.5 | – | – |

COMPACT AM/10 | COMPACT A/10 | 0.75 | 20 | 450 | 6.0 | 4.2 | 2.4 |

| 57 | 53 | 48.6 | 43.4 | 37.1 | 20 | – | – |

COMPACT AM/12 | COMPACT A/12 | 0.9 | 31.5 | 450 | 6.2 | 4.7 | 2.4 |

| 68 | 63.4 | 58.4 | 52.3 | 44.9 | 24 | – | – |

COMPACT AM/15 | COMPACT A/15 | 1.1 | 31.5 | 450 | 7.3 | 5.7 | 3.3 |

| 79 | 74.6 | 691 | 62.3 | 54 | 28 | – | – |

COMPACT BM/12 | COMPACT B/12 | 0.9 | 31.5 | 450 | 5.8 | 4.7 | 2.7 |

| – | 47.5 | 45.9 | 43.7 | 41.3 | 35.2 | 27.6 | 18 |

COMPACT BM/15 | COMPACT B/15 | 1.1 | 31.5 | 450 | 7.3 | 5.9 | 3.4 |

| – | 58 | 56 | 54 | 51.5 | 44.5 | 34.5 | 22 |