About Pump DW – DW VOX

AISI 304 stainless steel submersible pump and single-channel impeller (DW) or vortex impeller (DW VOX) for fixed and mobile installations. Available with two versions for piping connection. Suitable for domestic applications and large industrial wastewater lifting installations

Features

- Possibility to use in fixed and mobile installations

description Pump DW – DW VOX

AISI 304 stainless steel submersible pump and single-channel impeller (DW) or vortex impeller (DW VOX) for fixed and mobile installations. The DW – DW VOX electric pump has two versions for connection to pipes:

- Threaded for DW – DW VOX

- Flanged for DWF – DW VOXF

For further technical information see the Databook

- Evacuation of civil and industrial wastewater

- Drainage of wells or excavations

- Drainage of underwater areas

- General Handling of liquids, including those with solid and/or filamentary substances in suspension

- Emptying of seepage water

- Handling of dirty wastewater (sanitary services)

- Emptying of cesspits

Overview of technical data DW – DW VOX

| Flow rate | Up to 54 m³/h for DW Up to 48 m³/h for DW VOX |

| Total head | Up to 20 m for DW Up to 15.7 m for DW VOX |

| Max. temperature of the liquid | +40°C |

| Poles | 2 |

| Max. solids passage | 50 mm |

| Insulation class | F |

| Protection degree | IPX8 |

| Voltage | Single-phase 1~230V ± 10% Three-phase 3~400V ±10% |

| Max. immersion | 7 m with 10 m cable |

Material Pump DW – DW VOX

| Pump body | AISI 304 (EN 1.4301) |

| Impeller | AISI 304 (EN 1.4301) |

| Shaft | Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid) |

| Mechanical seal | upper part in Carbon/Ceramic/NBR (motor side) lower part in Silicon Carbide/NBR (pump side) |

pump DW – DW VOX

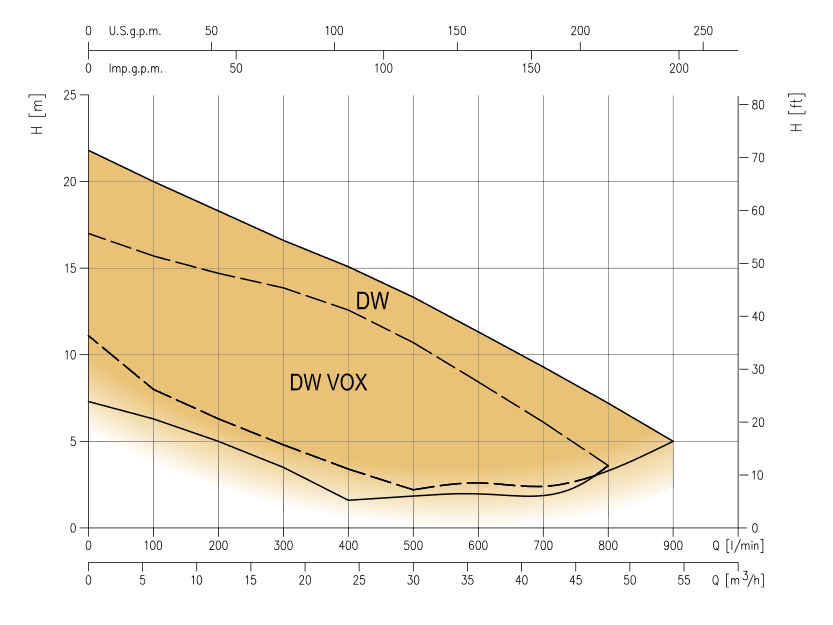

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906 Annex A

The curves refer to effective speed of asynchronous motors at 50 Hz

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of = 1 mm2/s (1 cSt)

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best

efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

Submersible electric pumps for waste water in AISI 304

Submersible electric pumps in stainless steel AISI 304 for waste water. They have a pump body,

impeller, motor cover, seal holder disc and motor case in AISI 304, while the shaft is in AISI 303.

Double mechanical seal with interposed oil chamber: the upper one in carbon/ceramic/NBR (motor

side), the lower one in SiC/SiC/NBR (pump side).

G20 cast iron spacer (only for DW – DW VOX 300).

Available single-phase versions with or without float.

Special Versions

– Single-channel impeller version (DW)

– Vortex type impeller version (DW VOX)

– Flanged version (DWF/DW VOXF)

INSTALLATION

The DW – DW VOX electric pumps are also available with a float switch, thus increasing the versatility of use. The choice of the use of the float switch requires the respecting of minimum installation spaces to guarantee correct operation of the pump itsel

Technical

- Total head from 2.2 to 20 m for DW

and from 1.6 a 15.7 m for DW VOX - Capacity from 6 a 54 m3/h for DW

and from 6 to 48 m3/h for DW VOX - Maximum immersion 7 m

- Maximum liquid temperature 40°C

- Maximum solid size passage 50 mm

Accessories

Descent device kit

- Guide hook DW – DW VOX in cast iron

- Fixed hook DW – DW VOX in cast iron

- On request version with special seal of Tungsten Carbide/Tungsten Carbide + FPM O-Ri

| Pump type | KW | Capacitor | Absorbed current | Q=Capacity | ||||||||||||

| 1P 230V 50Hz | 3P 400V 50Hz | µ F | Vc | 1~ | 3~ | l/min | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| m/h | 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | |||||||

| H=Total head | ||||||||||||||||

| DW 75m | DW 75 | 0.55 | 20 | 450 | 3.9 | 1.5 | 8 | 6.3 | 4.8 | 3.4 | 2.2 | – | – | – | – | |

| DW 100m | DW 100 | 0.75 | 25 | 450 | 5.9 | 2.1 | 10.6 | 8.7 | 7.1 | 5.5 | 4 | 2.6 | – | – | – | |

| DW 150m | DW 150 | 1.1 | 31.5 | 450 | 7.3 | 2.8 | 13.1 | 11.3 | 9.5 | 7.7 | 5.9 | 4.2 | 2.4 | – | – | |

| DW 200 | 1.5 | – | – | – | 36 | 16.6 | 15 | 13.3 | 11.4 | 9.5 | 7.5 | 5.4 | 3.3 | – | ||

| DW 300 | 2.2 | – | – | – | 5.0 | 20 | 18.3 | 16.6 | 15.1 | 13.3 | 11.3 | 9.3 | 7.2 | 5 | ||

| DW vox 75m | DW vox 75 | 0.55 | 20 | 450 | 3.9 | 1.4 | 6.3 | 5 | 3.5 | 1.6 | – | – | – | – | ||

| DW vox 100m | DW vox 100 | 0.75 | 25 | 450 | 5.8 | 2.1 | 7.9 | 6.7 | 5.3 | 3.7 | 1.9 | – | – | – | ||

| DW vox 150m | DW vox 150 | 1.1 | 31.5 | 450 | 7.3 | 2.8 | 10.2 | 9 | 7.6 | 6.1 | 4.1 | 2.1 | – | – | – | |

| DW vox 200 | 1.5 | – | – | – | 3.3 | 12.5 | 11.2 | 9.8 | 8.3 | 6.4 | 4.2 | 1.6 | – | – | ||

| DW vox 300 | 2.2 | – | – | – | 4.4 | 15.7 | 14.7 | 13.9 | 12.6 | 10.7 | 8.4 | 6.1 | 3.6 | – | ||