About Pump 6bhe

6″ submerged pump completely made of AISI 304 and AISI 316 (hydraulic only), extremely corrosion-resistant. Suitable for water supply.

Features

- Sturdy design, corrosion resistant

- Available in AISI 316

- Suitable for horizontal operation

description Pump 6bhe

6″ submerged pump entirely in AISI 304 and AISI 316 (hydraulic only). Its full stainless steel structure makes it extremely corrosion-resistant. It can be coupled with motors in water bath or oil bath.

The 6BHE(L) offers a wide range of operating temperatures and is, for particularly severe conditions, also available in AISI 316 steel.

For further technical information see the Databook

• Water supply systems for civil and industrial use

• Pressure boosting systems

• Community waterworks

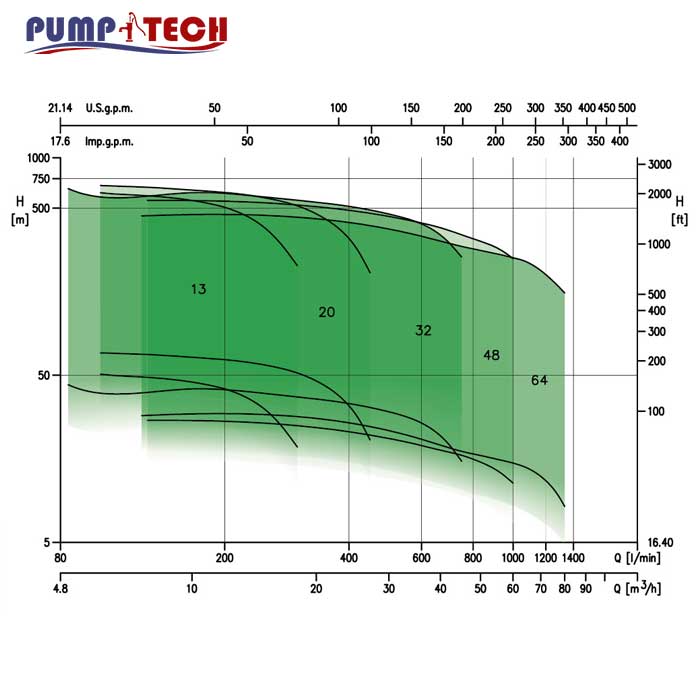

Overview of technical data 6bhe

| Flow rate | Up to 80 m³/h |

| Total head | Up to 700 m |

| Max. temperature of the liquid | -5°C ÷ +60°C |

| Poles | 2 |

| Insulation class | F (4″-6″ OY), (6″-8″ WY) B (4″ WY) |

| Protection degree | IP58 (OY), IP68 (WY) |

| Voltage | Three-phase 3~380-415V ±10% OY Three-phase 3~380-415V -10%+6% WY |

| Max. immersion | 350 m with motor in water bath 150 m with motor in oil bath |

| Max. sand content | 100 gr/m3 |

Material Pump 6bhe

| Impeller | AISI 304 (EN 1.4301) AISI 316 (EN 1.4401) for version L |

| Shaft | AISI 431 (EN 1.4057) AISI 316 (EN 1.4401) + AISI 329 (EN 1.4460) for version L |

| Outer casing | AISI 304 (EN 1.4301) AISI 316 (EN 1.4401) for version L |

| Discharge casing | AISI 304 (EN 1.4301) AISI 316 (EN 1.4401) for version L |

| Motor connection | AISI 304 (EN 1.4301) AISI 316 (EN 1.4401) for version L |

pump 6bhe

6” submersible centrifugal pump

6” submersible pump, stainless steel AISI 316 AISI 304 (6BHE) and (6BHEL), for deep wells.

Discharge casing, impeller, stages, support and diffuser are in AISI 304 or AISI 316 depending on the model. The shaft is in AISI 431 for 6BHE and AISI 316 + AISI 329 for 6BHEL.

They can be used for water supply from deep wells, for water distribution and pressurisation, irrigation systems, water treatment, filtering and reverse osmosis, industrial cooling systems, fountains and fire-fighting systems.

Technical

- Total head from 11.3 to 682 m

- Capacity from from 5 to 75 m3/h

- Maximum immersion: 350 m (water filled motor) 150 m

(oil filled motor) - Maximum liquid temperature 60°C

- Maximum sand content 100 gr/m3

- MEI > 0.4 (for all models except 6BHE (L) 13)

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906 Annex A

The curves refer to effective speed of asynchronous motors at 50 Hz

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity of ν = 1 mm2/s (1 cSt)

The NPSH curve is an average curve obtained in the same conditions of performance curves.

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

P2 = pump power input (shaft power)

η = pump efficiency

NPSH = net positive suction head required by the pump

MEI = minimum efficiency index

| Q=Capacity | Absorbed current (A) | Capacitor | KW | Pump type | ||||||||||||

| 1100 | 950 | 750 | 550 | 400 | 300 | 200 | 100 | l/min | Three-phase | Single -phase | Vc | µF | Tree-phase 230/400v 50Hz | Single-phase 230v 50Hz | ||

| 66 | 57 | 42 | 33 | 24 | 18 | 12 | 6 | m/h | 400V | 230V | ||||||

| H= Total head | ||||||||||||||||

| – | – | – | 5.1 | 6.9 | 7.9 | 8.9 | 9.5 | 2.5 | 4.4 | 6.8 | 450 | 31.5 | 1.1 | DWO 150 | DWO 150 M | |

| – | – | 5.8 | 8.6 | 10.5 | 11.5 | 12.3 | 12.7 | 3.5 | 6.1 | 9.0 | 450 | 40 | 1.5 | DWO 200 | DWO 200 M | |

| – | 7.5 | 9.7 | 11.7 | 12.9 | 13.8 | 14.5 | 15 | 4.8 | 8.3 | – | – | – | 2.2 | DWO 300 | – | |

| 7.6 | 9.8 | 12.4 | 14.3 | 15.6 | 16.3 | 16.9 | 17.5 | 6.4 | 11.0 | – | – | – | 3.0 | DWO 400 | – | |