DESIGN Booster Pumps SuperDAF

Single Pump Boosters

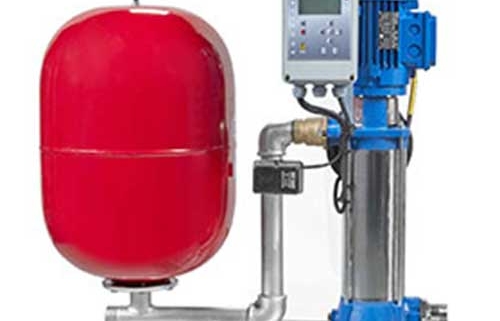

Booster pump set that has a single pump, multistage centrifugal pump with the motor block mounted on the pump.

- Number of pump stages range between 4 and 10.

- Quiet, comfortable and reliable, multi-stage pump package booster pumps

- Mechanical seal completely prevents leakage.

- All materials are ready for use.

- Assembly is easy and economical.

- Available in all stainless steel parts.

- Triphase available

TECHNICAL specifications Booster pump SuperDAF

| Flow Range | 0 – 4 m3/h |

| Head Range | 20 – 78 m |

| Operating Pressure | 8 Bar |

| Speed Range | 2900 – 3600 rpm |

| Suction Flange | 1 ¼” |

| Discharge Flange | 1 ¼” |

SCOPE OF APPLICATION Booster pump SuperDAF

- Apartments and residances

- Schools, business centers and small industrial installations

Advantages – Mounting and Start-Up booster pump SuperDAF

- SUPERDAF Series pumps are a set of booster containing a vertical, multistage cenrifugal pump and in which the motor is mounted on the pump.

- Stage number of the pump is from 4 up to 10.

- Completely stainless steel material option is available.

- Modular type with expansion tank.

- The control switch is provided safety and regularly operation of the booster. It does not reguire electrical panel.

- It is ready to connection to monophase socket by power cable with plug included in the delivery.

- Sealing is provided by mechanical seal.

- The level floater preventing waterless working, the quiet operated check-valve, the baseplate and the rubber feet preventing vibration are included in the delivery.

- The suction nozzle of the booster should be under from the level of water reservoir and water should reach to pump by its own weight. In different situations, please consult to MAS DAF Makine San. A.Ş.

- Suction line selecting in same diameter with suction nozzle as minimum should connect to booster evenly and as shortest; a strainer and a valve should be used on the suction line.

- Installation loads should not be put in booster.

- The level floater included in delivery should be hung down to the reservoir and by setting it should be fixed.

- Before working of booster, the pump and suction line should be filled with water and its air should be drained