About Pump 3L 4 SERIES

Centrifugal pump standardised to EN733 in AISI 304 stainless steel AISI 304 (3 SERIES), AISI 316 stainless steel (3L SERIES), with 2 or 4 poles motor and with Back pull-out

Features

- Sturdy construction

- Volute obtained with hydro-forming process

- High performances

description Pump 3L 4 SERIES

Centrifugal pump EN733 compliant and available in different materials:

- Stainless steel AISI 304 (3 SERIES)

- Stainless steel AISI 316 (3L SERIES)

- Stainless steel AISI 316 micro-cast for some models (3L SERIES)

EBARA Pumps Europe perfectly understands the different needs of the sectors where the pumps will be used. This is why it has created the 3 SERIES with 2 or 4 poles motors; a complete, innovative, reliable and efficient series to operate successfully even in the most difficult and heavy-duty conditions.

The distinguishing feature of 3 SERIES is the back pull-out design: a conformation that allows the removal of the impeller-motor block without disconnecting the pump body from the piping, thus allowing any type of maintenance.

The range consists of the:

- Monobloc 3(L)M SERIES

- With rigid coupling 3(L)S SERIES

- With elastic coupling 3(L)P SERIES

For the 3LM SERIES and 3LS SERIES the Z version is available, with the casing body without the support foot and with a new foot directly mounted to the motor bracket.

This solution allows the pump to stay in limited spaces where it is not possible to connect the foot of the standard 3 SERIES and, most importantly, allows to connect the pump in different positions thanks to the 90° rotation of the foot.

The 3(L)S SERIES and 3(L)P SERIES are available with ATEX certified hydraulics and motor (we suggest contacting the sales network for the ATEX version).

For further technical information see the Databook

- Heating, ventilation and air-conditioning systems

- Water supply for civil, agricultural and industrial plants

- Pressurisation

- Firefighting systems

- Industrial liquid handling systems

- Irrigation

- Cooling towers

- Swimming pools

- Drainage

- Washing systems

Overview of technical data 3L 4 SERIES

| Flow rate | Up to 240 m³/h |

| Total head | Up to 100 m |

| Max. working pressure | 10 bar |

| Max. temperature of the liquid | -5°C ÷ +90°C for standard models -5°C ÷ +110°C for H, HS, HW, HSW versions -20°C ÷ +120°C for E version |

| MEI | > 0.4 |

| Poles | 2 and 4 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% (up to and including 4kW) Three-phase 3~400/690V ±10% (from 5.5kW and above) |

Material Pump 3L 4 SERIES

| Pump body | Stainless steel AISI 304 (EN 1.4301) for SERIE 3 Stainless steel AISI 316L (EN 1.4404) for SERIE 3L Stainless steel AISI 316 (EN 1.4401) precision-cast for SERIES 3L 65-250 80-160/200/250 |

| Impeller | Stainless steel AISI 304 (EN 1.4301) for SERIE 3 AISI 316L (EN 1.4404) for 3L SERIES 32, 40, 50 AISI 316 (EN 1.4401) precision-cast for 3L SERIES 65, 80 |

| Shaft | Stainless steel AISI 304 (EN 1.4301) for 3 SERIES Stainless steel AISI 316L (EN 1.4404) for 3L SERIES Duplex for 3L SERIES 65-250, 80-200/30, 80-200/37, 80-250 |

| Mechanical seal | Standard = Ceramic/Carbon/NBR H = Graphite/Ceramic/FPM HS = Silicon Carbide/Silicon Carbide/FPM HW = Tungsten Carbide/Tungsten Carbide/FPM HSW = Silicon Carbide/Tungsten Carbide/FPM E = Graphite/Ceramic/EPDM |

| Motor support | Aluminium – cast iron |

pump 3L 4 SERIES

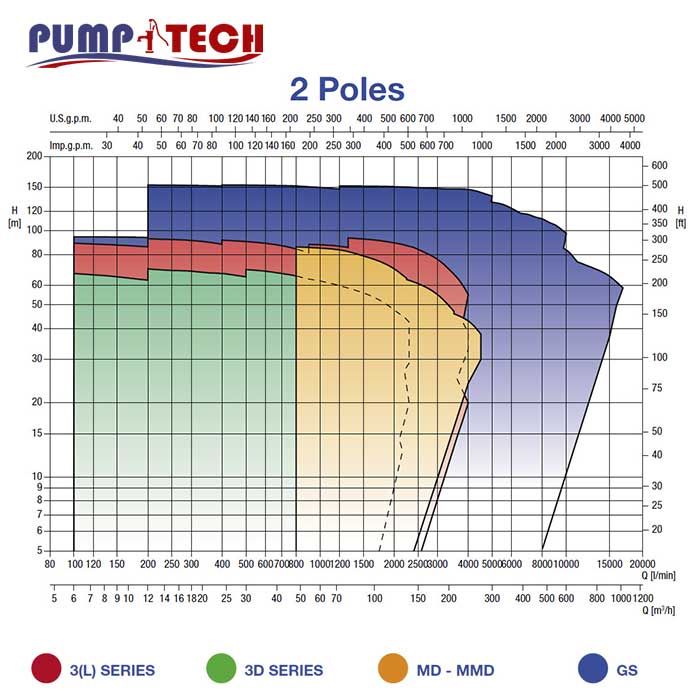

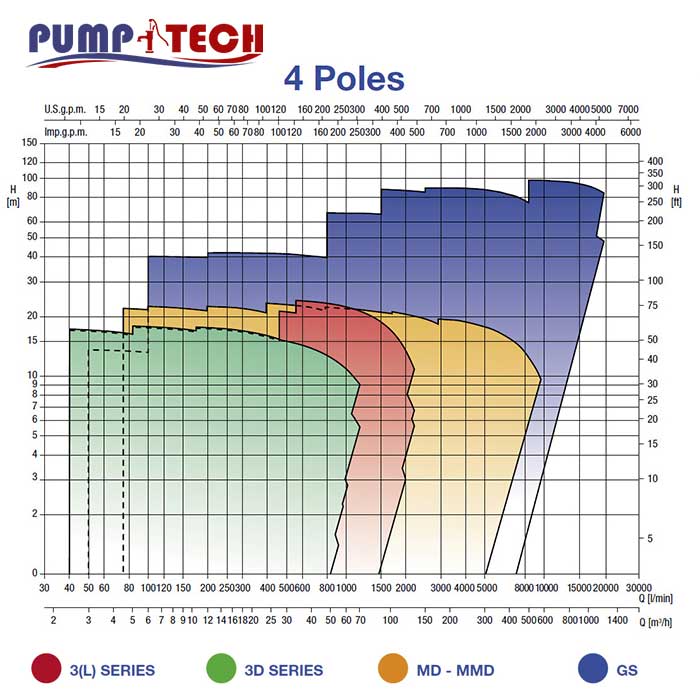

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of = 1 mm2/s (1 cSt)

The NPSH curve is an average curve obtained in the same conditions of performance curves.

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

P2 = pump power input (shaft power)

= pump efficiency

NPSH = net positive suction head required by the pump

MEI = minimum efficiency index