About Pump 3D4-SERIES

Standardised cast iron centrifugal pump with AISI 304 and AISI 316 steel impeller, axial suction and radial discharge with 2 or 4 poles motors. Available in three versions. Equipped with Back pull-out design that allows the motor, coupling, bracket and impeller to be removed without compromising the pump body or disassembling the piping. Many types of mechanical seals can be mounted on electric pumps to meet different requirements. Suitable for application in heating and air conditioning systems, water supply of civil, agricultural and industrial plants, pressurisation and fire-fighting.

Features

- Sturdy construction

- High efficiency

- Impeller in stainless steel

description Pump 3D4-SERIES

Standardised cast iron centrifugal pump with AISI 304 and AISI 316 steel impeller, axial suction and radial discharge with 2 or 4 poles motors. The 3D SERIES is equipped with Back pull-out design that allows the motor, coupling, bracket and impeller to be removed without compromising the pump body or disassembling the piping.

The many types of mechanical seal that can be mounted on the electric pumps allow the use of special materials. Therefore, they can adapt to different needs based, for example, on the type of liquid, temperature or other factors of use, covering, depending on the model, a wide range of temperatures.

The 3D SERIES is divided into three versions:

- 3D SERIES monoblock with extended shaft

- 3DS SERIES with rigid coupling and IEC Standard motor

- 3DP SERIES with elastic coupling and IEC Standard motor

For further technical information see the Databook

- Heating, ventilation and air-conditioning systems

- Water supply for civil, agricultural and industrial plants

- Pressurisation

- Firefighting systems

- Industrial liquid handling systems

- Irrigation for farms, sports facilities

- Washing systems

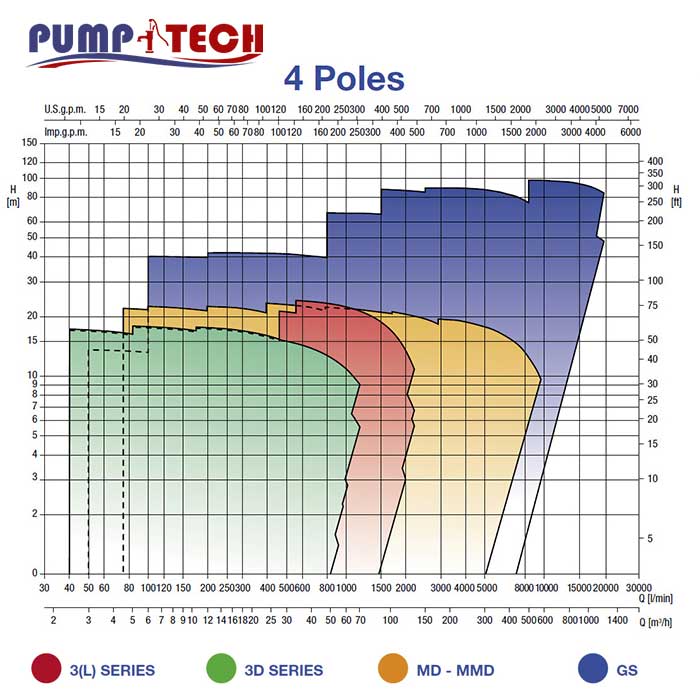

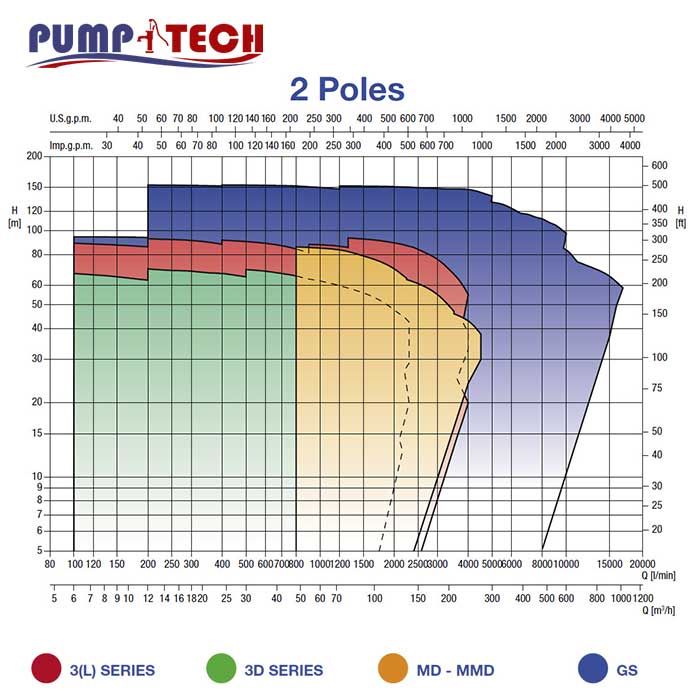

Overview of technical data 3D4-SERIES

| Flow rate | Up to 138 m³/h |

| Total head | Up to 70,0 m |

| Max. working pressure | 10 bar |

| Max. temperature of the liquid | -5°C ÷ +90°C -5°C ÷ +110°C for H, HS, HW, HSW versions -5°C ÷ +120°C for E version |

| MEI | > 0.4 |

| Poles | 2 and 4 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% Three-phase 3~400/690V ±10% |

Material Pump 3D4-SERIES

| Pump body | Cast iron |

| Impeller | AISI 304 (EN 1.4301) AISI 316 (EN 1.4401) for 3D 65 |

| Shaft | Stainless steel Stainless steel 304 (EN 1.4301) Stainless steel 420 (EN 1.4021) (MMD) |

| Mechanical seal | Standard = Ceramic/Carbon/NBR H = Graphite/Ceramic/FPM HS = Silicon Carbide/Silicon Carbide/FPM HW = Tungsten Carbide/Tungsten Carbide/FPM HSW = Silicon Carbide/Tungsten Carbide/FPM E = Graphite/Ceramic/EPDM |

| Motor support | Cast iron for 32-200/3, 15, 18.5 and 22 kW models Aluminium for the rest of the range |

pump 3D4-SERIES

Back pull out design and shielded bearings

This configuration ensures disassembly and inspection of the pump without having to remove it from the system piping. Furthermore, the use of shielded bearings eliminates the need to add or replace lubricating oil.

This solution facilitates and speeds up maintenance

Bare axis pump and electric pump

GS models are available both in the bare axis version and in the electric pump version, with motor powers up to 355 kW. The available motors are 2 or 4 poles, 50 Hz, IE3 efficiency, coupled with inverter

Sealing options

The seal is available in two different versions:

• SiC/Carbon/EPDM mechanics for liquid temperature up to 120°C

• A packing that guarantees resistance to wear and ensures that the tightness of the entire system is monitored visually

Technical :

Type of product

Standardised single-stage centrifugal pumps (EN 733)

Liquid temperature range

from -10°C to + 90°C for the standard version of the 3-3D-MD-MMD SERIES (depending on the model)

from -10°C to + 120°C for the Model GS

from -20°C to + 120°C for the special versions of the 3-3D-MD SERIES (depending on the model)

Maximum working pressure

10 bar (16 for Model GS)

Materials available

Stainless steel AISI 304 for 3 SERIES

Stainless steel AISI 316L for 3L SERIES

Micro-cast stainless steel AISI 316 for the 3L SERIES 65-250, 3L SERIES 80

Cast iron for the 3D SERIES-MD-MMD e Model GS

Regulations

It complies with regulations ErP 547/2012 (index MEI > 0.4),

640/2009 (motors in IE3 efficiency class)

EN 733