About Pump EVMS-K

Vertical multistage surface pump in AISI 304 steel (EVMS), in AISI 316L (EVMSL) or in cast iron (EVMSG) complete with integrated E-SPD frequency converter

Features

- Available in AISI 316

- Available in cast iron

- High efficiency

- Different connections available

- Easy maintenance

- PZH

Technical

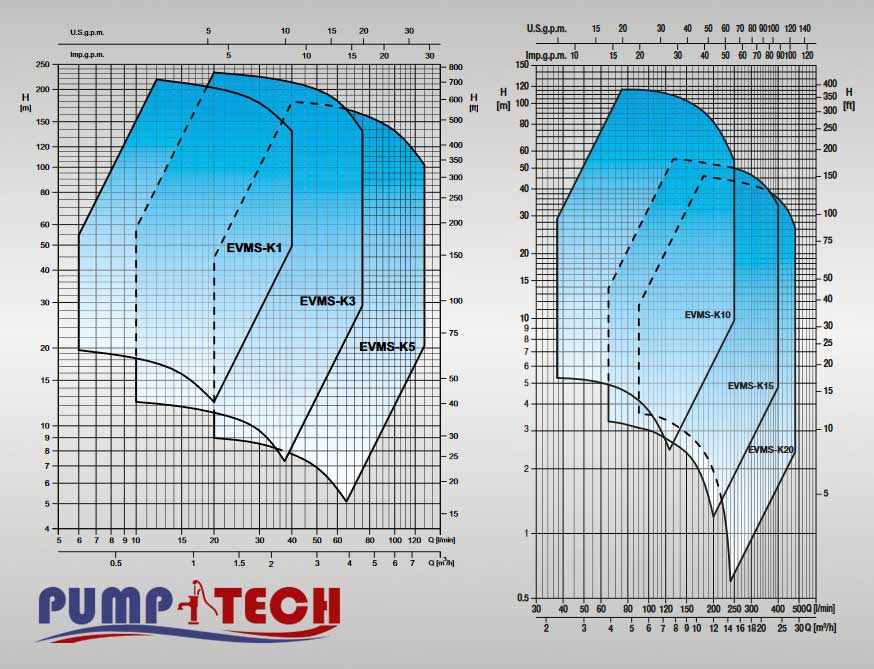

- Flow rate 1, 3, 5, 10, 15, 20 m³/h (nominal flow rate)

- Total head 243 m

- Max. working pressure 16, 25 bar

- Max. temperature of the liquid from 0ºC to 80ºC

description Pump EVMS-K

Vertical multistage surface pump in AISI 304 steel (EVMS), in AISI 316L (EVMSL) or in cast iron (EVMSG) complete with integrated E-SPD frequency converter. On the one hand the highly innovative technology of the EBARA EVMS with patented Shurricane® impeller and on the other hand E-SPD, the air cooled inverter, capable of varying the speed continuously and operating on any working point, consequently optimising performances and consumption according to the system’s requirements.

For further technical information see the Databook

- Water supply for distribution networks related to the building service sector

- Water supply for industry in general

- Irrigation

Overview of technical data EVMS-K

| Flow rate | 1, 3, 5, 10, 15, 20 m³/h (nominal flow rate) |

| Total head | 243 m |

| Max. working pressure | 16, 25 bar |

| Max. temperature of the liquid | from 0ºC to 80ºC |

| MEI | > 0.7 |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 230V±10% for MT version up to 2,2kW Three-phase 400V±10% for TT version up to 4kW |

Material Pump EVMS-K

| Impeller | AISI 304 (EN 1.4301) AISI 316L (EN 1.4404) for EVMSL |

| Shaft | AISI 304 (EN 1.4301) or AISI 329A (EN 1.4462) (depending on model) AISI 316L (EN 1.4404) or AISI 329A (EN 1.4462) for EVMSL (depending on model) |

| Mechanical seal | Silicon Carbide/Carbon/EPDM or FPM Silicon Carbide Graphite/Silicon Carbide/EPDM or FPM |

| Motor support | Cast iron ENGJL-200 EN1561 |

| Outer casing | AISI 304 (EN 1.4301) AISI 316L (EN 1.4404) for EVMSL |

| Base | AISI 304 (EN 1.4301) and ASTM CF8 (EN 1.4308) for EVMS Cast iron for EVMSG AISI 316L (EN 1.4404) and ASTM CF8 (EN 1.4308) for EVMSL |

pump EVMS-K

TESTS AND TRIALS

Before shipping, all EBARA pressurisation units (or components) are subject to hydraulic, mechanical and electrical testing.

MECHANICAL AND HYDRAULIC TESTS

- Pump direction of rotation

- Mechanical testing of moving parts and running noise (on each pump)

- Tightness test with delivery port closed and nameplate rating tests

ELECTRICAL TESTS

- Earthing system continuity

- Applied voltage (dielectric rigidity)

- Insulation resistance

Principle of Operation of UNITS

EVMS-K units with E-SPD are designed to operate with each pumps controlled by an INVERTER installed on board its motor, on the terminal box. The system is controlled by an INVERTER in relation to the reference signal supply by a pressure transmitters (4 – 20 mA passive). As the system pressure varies, the pump varies its rotary speed to restore it to the setpoint. If the water demand exceeds the capacity, the pump goes into regulation mode to maintain the pressure setpoint. If the water demand drops off, the pressure tends to increase and the pump gradually reduces its speed to restore the correct operating pressure. Once the system pressure has been restored and the water demand is 0, the pump switches off automatically