About Booster 2GPE with E-SPD

Pressure boosters with two three-phase horizontal or vertical pumps, with hydraulics in AISI 304 or AISI 316 and special mechanical seals on request, with integrated E-SPD inverter. Used for water supply for distribution networks in the building services and general industry sectors and domestic pressurisation

Features

- Versatility

- Compact dimensions

description Booster 2GPE with E-SPD

Centrifugal pump fitted with an open radial flow impeller in AISI 304 stainless steel, also making it suitable for pumping liquids that are not completely clean, but with solid parts up to 19 mm in diameter.

The DWO electric pump’s pressed AISI 304 pump body is obtained through the hydroforming process, providing sturdy construction, hydraulic efficiency and reliability.

For further technical information see the Databook

- Washing of vegetables, meat, fish and molluscs

- Industrial end-of-cycle washing systems, washing and surface finishing of metal pieces, cans, washing of bottles, jars, glass containers, crates, and baskets, etc.

- Communal dishwashers, glasswashers, cup washers, spray booths

- Liquid handling, evacuation and transfer

Overview of technical Booster 2GPE with E-SPD

| Max. working pressure | 10 bar for 2GPE CVM/MATRIX/COMPACT 16 bar for 2GPE EVMSG |

| Max. temperature of the liquid | +40°C for 2GPE COMPACT/CVM +80°C for 2GPE MATRIX/EVMSG |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP44 for 2GPE COMPACT/CVM IP55 for 2GPE MATRIX/EVMS |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~400V ±10% |

| Max. working pressure | 10 bar for 2GPE CVM/MATRIX/COMPACT 16 bar for 2GPE EVMSG |

| Max. temperature of the liquid | +40°C for 2GPE COMPACT/CVM +80°C for 2GPE MATRIX/EVMSG |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP44 for 2GPE COMPACT/CVM IP55 for 2GPE MATRIX/EVMS |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~400V ±10% |

Booster 2GPE with E-SPD Ebara

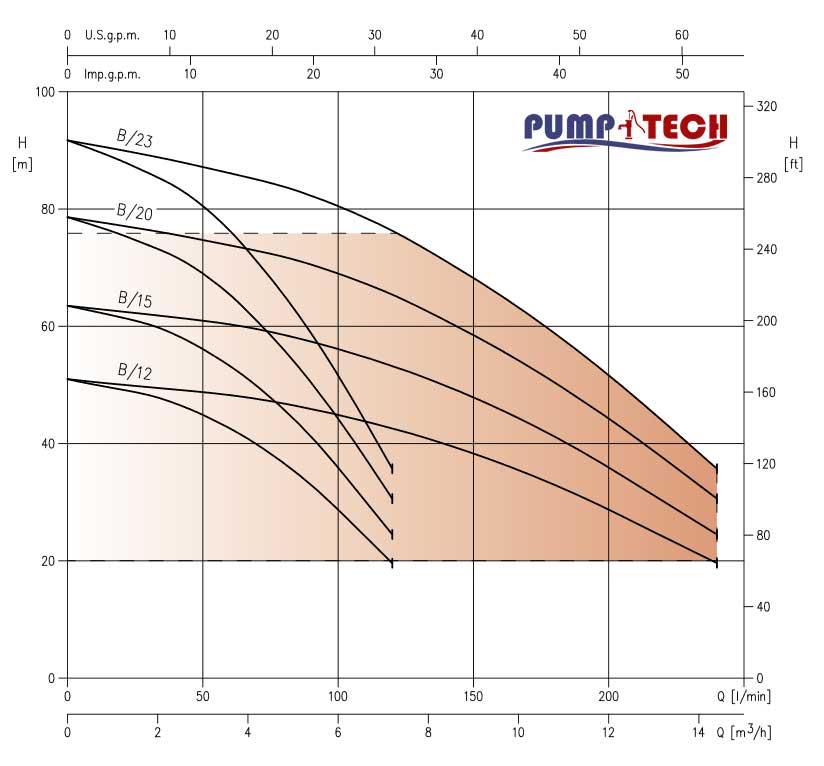

SPECIFICHE DELLE CURVE 2GP(E)

Le specifiche riportate di seguito si riferiscono alle curve illustrate nelle pagine successive.

Tolleranze in conformità con ISO 9906 Allegato A

Le curve si riferiscono a una velocità effettiva dei motori asincroni a 50 Hz

Le misurazioni sono state effettuate con temperatura dell’acqua pulita di 20°C e con viscosità cinematica

n = 1 mm2/s (1 cSt)

La curva NPSH è una curva media ottenuta nelle stesse condizioni delle curve di prestazione.

Le curve continue indicano l’intervallo di funzionamento consigliato. La curva tratteggiata è solo indicativa.

Al fine di evitare il rischio di surriscaldamento, le pompe non devono essere utilizzate a una portata inferiore al

10% della portata di efficienza massima.

Spiegazione dei simboli:

Q = portata

H = prevalenza totale

P2 = ingresso alimentazione pompa (potenza albero)

h = efficienza della pompa

NPSH = prevalenza netta di aspirazione positiva richiesta dalla pompa