VDKM Main applications

The VDKM pump makes it possible to transport food products through a closed tube. This is not only more hygienic, but it also saves enormous space compared to the traditional conveyor belts, which are open and also obstruct free passage in the company.

VDKM Design

VDKM pumps are ideally suited for gently pumping solid food products in water, such as whole or cut vegetables (beans, peas, carrots, cucumbers, cabbage, maize, onions, etc.), fruit (apples, pears, cherries) and sea creatures (shrimp, mussels, cockles).

VDKM benefits pump

- Gentle and damage-free pumping

- Easy maintenance: short downtimes

- Extremely large passage

- Electropolished stainless steel 304L: no rusting & easy to clean

- Monobloc design: space saving

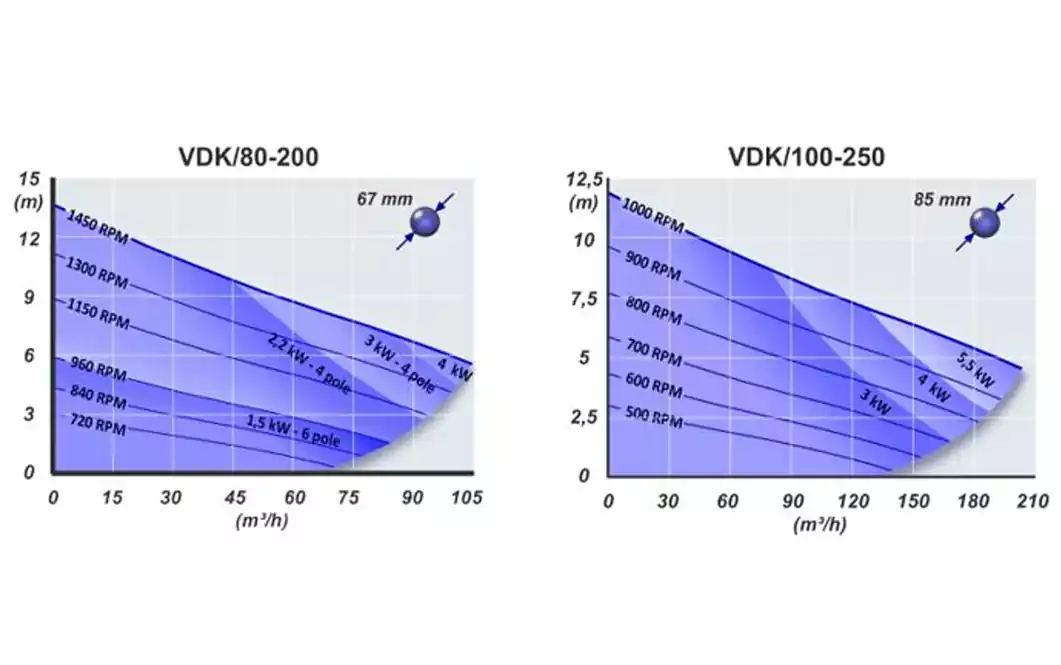

Overview of technical data VDKM

| Max. flow | 180 m3/h |

| Differential head | 13 m |

| Max. Inlet pressure | – |

| Viscosity | 100 cP |

| Max. temperature | 80 °C |

| Impeller type | Channel impeller |

| Max. free passage | 85 mm |

| Max. drive power | 5.5 kW |

| Speed | 1450 rpm |

| Available frequency | 50/60 hz |

| Materials wetted parts | Stainless steel 304 or similar |

| Mechanical seal configuration | Single |

| Available O-ring materials | NBR (FDA) |

| Connections | Industrial |

| Surface Finish | industrial finish: welds are not hand polished final surface treatment: electropolished |

| Certificates | 1935/2004 EC. FDA. EAC |