FP60 Main applications

The FP60 food pump series are mainly used for pumping clean and slightly contaminated liquids coming from dairies, cheese factories, breweries, distilleries, beverage industry, etc.

They are often used as process pump for heat exchangers, filtration units, filling machines, brine injectors, batter machines and CIP cleaning systems.

Typical liquids are milk, whey, curd, batter, brine, beer, CIP, alcohol, etc.

FP60 Design

The Packo stainless steel centrifugal pumps of the FP60 series are a low cost food grade pump mainly used for pumping clean and slightly contaminated liquids coming from egg dairies, cheese factories, breweries, distilleries, beverage industry, etc. They are often used as process pumps for heat exchangers, filtration units, filling machines, brine injectors, batter machines and CIP cleaning systems.

FP60 benefits pump

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: easy to clean

- Easy construction and easy maintenance: less downtime

- Easy to install

- Best value for money

FP60 Description

The Packo stainless steel centrifugal pumps of the FP60 series are a low cost food grade pump mainly used for pumping clean and slightly contaminated liquids coming from egg dairies, cheese factories, breweries, distilleries, beverage industry, etc. They are often used as process pumps for heat exchangers, filtration units, filling machines, brine injectors, batter machines and CIP cleaning systems.

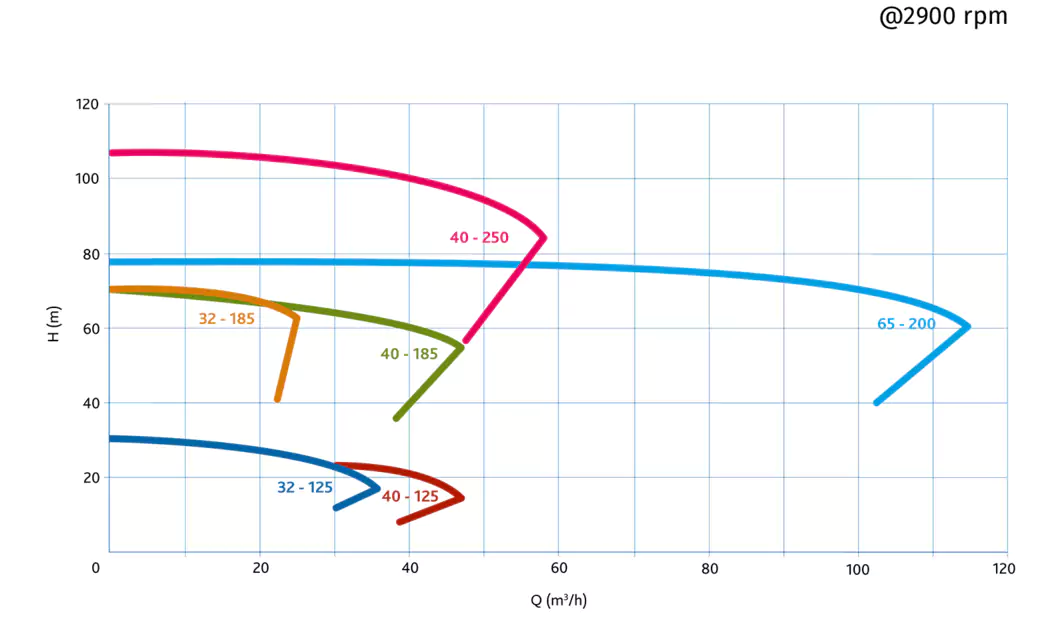

FP60 Curve

Overview of technical data FP60

| Max. flow | 40 m3/h |

| Differential head | 27 m wc |

| Max. Inlet pressure | 3 bar |

| Viscosity | 500 cP |

| Max. temperature | 95 °C |

| Impeller type | Open |

| Max. free passage | 15 mm |

| Max. drive power | 2.2 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single, quench |

| Available material O-ring | EPDM, FKM |

| Connections | Hygienic fittings |

| Surface finish | Hygienic quality, internal welds hand polished + electropolished (casing 0.8 μm – impeller 3.2 μm) |

| Certificates | 1935/2004 EC. MEI. ATEX. FDA. EAC |