About Pump MULTIGO

AISI 304 stainless steel vertical multistage centrifugal pump, equipped with an internal motor cooled by the pumped liquid that allows it to be used both on the surface and in a submerged configuration

Features

- Easy maintenance

- Practical and easy to use

- Silent

Technical

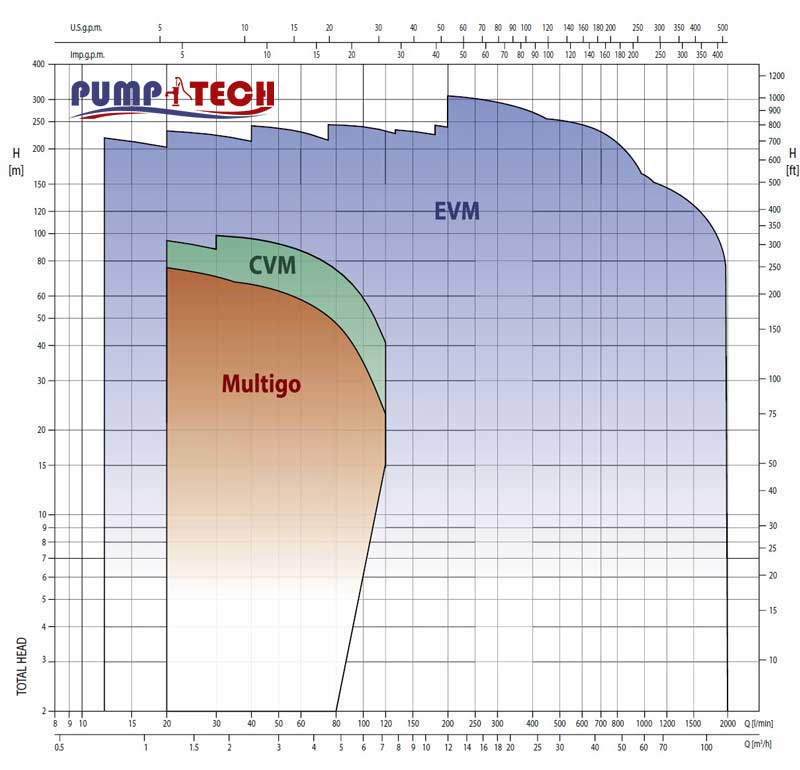

- Total head from 75.7 to 13.4 m

- Capacity from 1.2 to 7.2 m3/h

- Hydraulic efficiency index MEI > 0.4

- Liquid temperature up to +40°C

- Maximum suction depth: 6 m

- IP 68 protection degree

description Pump MULTIGO

Vertical multistage centrifugal pump in AISI 304 stainless steel, equipped with a motor cooled by the pumped liquid that makes it unique in terms of versatility of use, both in surface and submerged configuration, and of silence, reducing the vibrations caused by the hydraulic part.

The MULTIGO vertical multistage centrifugal electric pump has a double mechanical seal in the oil chamber to ensure continuous lubrication and maximum reliability. The MULTIGO is available also as in-line version.

For further technical information see the Databook

- Pressure boosting

- Pressure boosting systems

- Irrigation

- Washing systems

- Clean water harvesting

Overview of technical data MULTIGO

| Flow rate | 1.2 to 7.2 m³/h |

| Total head | From 75.7 to 13.4 m |

| Max. working pressure | 10 bar |

| Max. temperature of the liquid | +40°C |

| Max. suction depth | 6 m with 5 m cable |

| MEI | > 0.4 |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP68 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump MULTIGO

| Pump body | AISI 304 (EN 1.4301) |

| Impeller | PPE+PS with glass fibres |

| Shaft | Stainless steel 431 (EN 1.4057) |

| Mechanical seal | Ceramic/Carbon/NBR |

| Motor support | AISI 304 |

pump MULTIGO

MULTIGO is a vertical multistage centrifugal electric pump with an outer casing, a motor cover and a seal holder disc in AISI 304. The components of the hydraulics, i.e. impeller, diffuser and spacer, are made of polypropylene and polystyrene (PPE + PS) reinforced with glass fibres.

- Constructively it presents a double mechanical seal in an oil chamber, to ensure continuous lubrication and maximum reliability. Both seals, on the motor side and on the pump side, are made of Ceramic/Carbon/NBR.

- Cooling of the motor is guaranteed by the passage of the pumped fluid, so that this pump can be used both in the surface and in the submerged configuration. It is precisely this feature that makes it suitable for different applications.

- All the MULTIGO models are supplied with 5 meters of H07RN-F cable.

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906 Annex A The curves refer to effective speed of asynchronous motors at 50 Hz

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity of ν = 1 mm2/s (1 cSt)

The NPSH curve is an average curve obtained in the same conditions of performance curves.

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

P2 = pump power input (shaft power)

η = pump efficiency

NPSH = net positive suction head required by the pump

MEI = minimum efficiency index

The minimun efficiency index (MEI) is a measure of the quality of a pump size in respect to its mean efficiency. The minimum efficiency index is based on the hydraulic efficiency and on the head at the best efficiency point.

Pump type | KW | Capacitor | Absorbed current | Q=Capacity | ||||||||||

Single-phase 230V 50Hz | Three-phase 400V 50Hz | F | V | 1 | 3 400V | l/min | 20 | 30 | 40 | 60 | 80 | 100 | 120 | |

m/h | 1.2 | 1.8 | 2.4 | 3.6 | 4.8 | 6 | 7.2 | |||||||

H=Total head | ||||||||||||||

MULTIGO M 40/08 | MULTIGO 40/08 | 0.6 | 16 | 450 | 4.3 | 1.9 |

| 43.3 | 40.2 | 36.3 | 26.1 | 13.4 | – | – |

MULTIGO M 40/10 | MULTIGO 40/10 | 0.75 | 20 | 450 | 5.7 | 2.2 |

| 54.1 | 50.2 | 45.4 | 32.6 | 16.8 | – | – |

MULTIGO M 40/12 | MULTIGO 40/12 | 0.9 | 20 | 450 | 6.8 | 2.4 |

| 64.9 | 60.2 | 54.5 | 39.2 | 20.2 | – | – |

MULTIGO M 40/15 | MULTIGO 40/15 | 1.1 | 31.5 | 450 | 7.3 | 3.0 |

| 75.7 | 70.3 | 63.6 | 45.7 | 23.5 | – | – |

MULTIGO M 40/12 | MULTIGO 80/12 | 0.9 | 20 | 450 | 6.4 | 2.3 |

| – | 45.6 | 44 | 38.8 | 32 | 23.2 | 15.2 |

MULTIGO M 80/15 | MULTIGO 80/15 | 1.1 | 31.5 | 450 | 7.5 | 3.1 |

| – | 57 | 55 | 48.5 | 40 | 28 | 19 |

– | MULTIGO 80/20 | 1.5 | – | – | – | 3.5 |

| – | 68.4 | 66 | 58.2 | 48 | 34.8 | 22.8 |