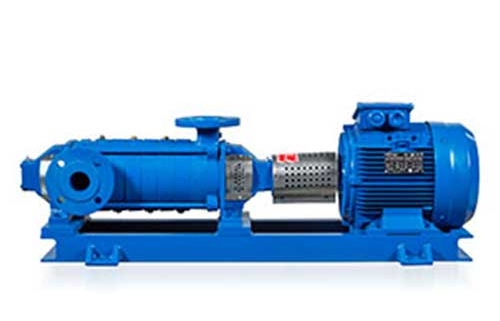

DESIGN Pumps KMU

- KMU series, multistage, horizontal centrifugal pumps.

- High-efficiency stainless steel impeller is manufactured using precision molding technology used.

- Single entry enclosed type impeller is dynamically balanced

- The pump and the motor are connected by means of a flexible coupling on a common base plate. The flanges are compatible with DIN 2535.

- Pump shaft is designed for easy maintenance and repair with problem-free dismantling.

- When viewed from the motor end, the suction flange is opposite the motor and on the left, whereas the discharge flange is adjacent to and above the motor.

- Suction and discharge ports can be fitted in different directions and 90° apart.

TECHNICAL specifications pump KMU

| Suction Flange | DN 25…DN 50 (PN 40) (DIN 2535) |

| Discharge Flange | DN 25…DN 50 (PN 40) (DIN 2535) |

| Operating Pressure | 25 Bar |

| Stage Number | 2-14 |

| Flow Range | 1-16 m³ / h |

| Head Range | 10-280 m |

| Temperature Range | -10..1100C; mechanical seal |

| -10..900C; soft packing | |

| Speed | Up to 3600 rpm |

SCOPE OF APPLICATION pump KMU

In pumping of pure or relatively clean liquids in:

- Boilers and condensation process.

- Health and hygienic processes.

- ndustrial applications.

- Shipyards, mines and power installations, filtration units.

- Drinking water supply and distribution centers.

- Water supply in high buildings.

- Water treatment systems.

- Industrial installations for provision of process water

Bearings pump KMU

On both ends there are one bearing housing equipped with maintenance-free antifriction bearings, which are greased for life with high-temperature grease. Thrower on the shaft prevent leakage fluid from getting into bracket.

Pumped Liquids pump KMU

Thin, clean, non-aggressive and non-explosive liquids free from solid particles and fibres.

- Fresh water, potable water, boiler feed water, industrial water, sea and brackish water, hot water, condensate, lye, etc.

For special applications, please consult to MAS DAF MAKİNA SAN.A.Ş

Shaft Seal pump KMU

Pumps are supplied as standard soft packing. Lantern ring on suction side for water sealing and lubricating of packing. Sealing section of pump shaft are protected by Stainless Steel (1.4021/AISI 420) sleeves.

- Uncooled stuffing box is standard. (Up to 90 °C)

- Uncooled mechanical seal is optional. (Up to 110 °C)

Shaft pump KMU

Chromium steel (1.4021/AISI 420) fine grained shafts are used on KMU pumps.