About Pump LPS

AISI 304 stainless steel in-line centrifugal pump, with suction and discharge on the same axis, equipped with high-efficiency ventilated motor. Suitable for circulation, civil and industrial heating systems

Features

- Practical and easy to use

- Silent

description Pump lps

In-line centrifugal pump with hydraulics in AISI 304 stainless steel, with suction and discharge positioned on the same axis.

The LPS is equipped with high-efficiency ventilated motors that make it versatile and very suitable for large capacities and large systems.

For further technical information see the Databook

• Circulation, civil and industrial heating systems

• Handling of domestic hot water, low-pressure liquids in general

• Cooling and air conditioning systems

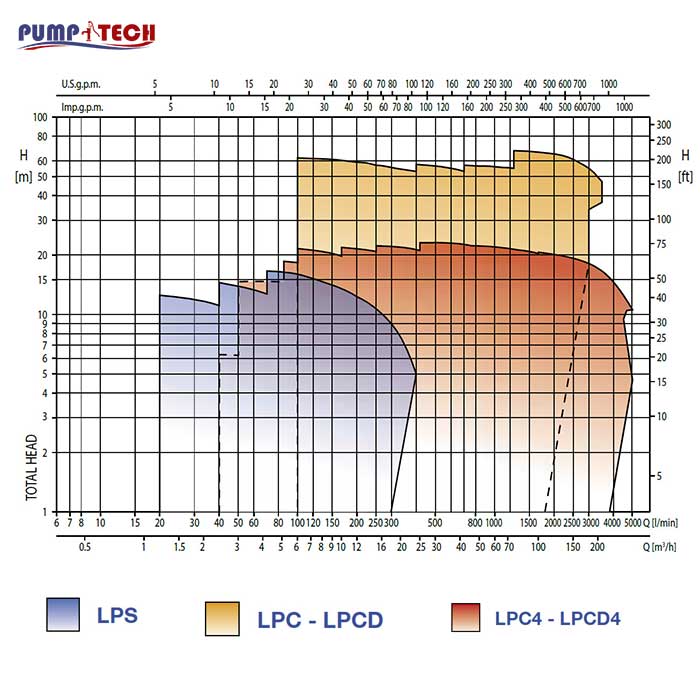

Overview of technical data lps

| Flow rate | from 1.2 to 12 m³/h |

| Total head | From 2.4 to 12.5 m |

| Max. working pressure | 2 bar for LPS single-phase and LPS 25 three-phase 4 bar for LPS 32-40-50 three-phase |

| Max. temperature of the liquid | -10°C ÷ +100°C |

| MEI | > 0.4 |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump lps

| Pump body | AISI 304 (EN 1.4301) |

| Impeller | AISI 304 (EN 1.4301) |

| Shaft | Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid) |

| Mechanical seal | Ceramic/Carbon/NBRH |

| Motor support | Aluminium |

pump lps

In-line centrifugal pumps with pump body, impeller and seal holder disc in AISI 304 stainless steel, with ventilated 2-pole motor. Suitable for circulation systems, they are used to pump both hot water for domestic hot water and heating systems, and chilled water for air conditioning and cooling, both in civil and industrial systems.

|

Pump type |

KW |

Capacitor |

Absorbed Current (A) |

Q=Capacity |

||||||||||||||

|

Single-phase 230v 50hz |

Three-phase 230/400v 50hz |

µF |

Vc |

1~ |

3~ |

l/min |

20 |

40 |

70 |

100 |

120 |

150 |

200 |

250 |

320 |

400 |

||

|

230V |

400V |

m/h |

1.2 |

2.4 |

4.2 |

6 |

7.2 |

9 |

12 |

15 |

19.2 |

24 |

||||||

|

H=Total Head |

||||||||||||||||||

|

LPS 25/08 M |

25/08 M |

0.08 |

12.5 |

450 |

1.51 |

1.7 |

1.01 |

6.5 |

5 |

2.4 |

– |

– |

– |

– |

– |

– |

– |

|

|

LPS 25/15 M |

25/15 M |

0.15 |

12.5 |

450 |

1.67 |

1.8 |

1.03 |

9.3 |

7.8 |

4.9 |

– |

– |

– |

– |

– |

– |

– |

|

|

LPS 25/25 M |

25/25 M |

0.25 |

12.5 |

450 |

2.04 |

1.9 |

1.11 |

12.5 |

11.1 |

8.4 |

– |

– |

– |

– |

– |

– |

– |

|

|

LPS 32/25 M |

32/25 M |

0.25 |

12.5 |

450 |

2.0 |

1.8 |

1.03 |

– |

10.7 |

9.1 |

7.2 |

5.9 |

3.9 |

– |

– |

– |

– |

|

|

LPS 32/40 M |

32/40 M |

0.4 |

12.5 |

450 |

2.74 |

2.2 |

1.25 |

– |

14.5 |

12.7 |

10.6 |

9.2 |

7 |

– |

– |

– |

– |

|

|

LPS 40/25 M |

40/25 M |

0.25 |

12.5 |

450 |

1.98 |

1.9 |

1.09 |

– |

– |

7.8 |

7.1 |

6.6 |

5.6 |

3.7 |

– |

– |

– |

|

|

LPS 40/40 M |

40/40 M |

0.4 |

12.5 |

450 |

2.75 |

2.2 |

1.25 |

– |

– |

11.3 |

10.4 |

9.9 |

8.7 |

6.9 |

4.4 |

– |

– |

|

|

LPS 40/75 M |

40/75 M |

0.75 |

25 |

450 |

4.86 |

4.0 |

2.29 |

– |

– |

16.6 |

16 |

15.2 |

14.1 |

12.3 |

10.1 |

– |

– |

|

|

LPS 50/40 M |

50/40 M |

0.4 |

12.5 |

450 |

2.74 |

2.2 |

1.25 |

– |

– |

– |

– |

9.1 |

8.8 |

7.4 |

5.9 |

3.5 |

– |

|

|

LPS 50/75 M |

50/75 M |

0.75 |

25 |

450 |

4.9 |

3.9 |

2.26 |

– |

– |

– |

– |

13.8 |

13.3 |

12.3 |

10.7 |

8.2 |

5 |

|

|

LPS 50/150 M |

50/150 M |

1.5 |

35 |

450 |

8.07 |

5.7 |

3.31 |

– |

– |

– |

– |

19.8 |

19.3 |

18.7 |

17.8 |

16 |

13.7 |

|