NP60 Main applications

The NP60 pumps are mainly used for pure as well as slightly contaminated liquids up to a maximum viscosity of 500 cP.

They are often used as process pump for the washing of textiles, for water treatment, but also for pumping solvents, alcohols and chemicals.

NP60 Design

The Packo stainless steel centrifugal pumps of the NP60 series are a low-cost industrial pump used for handling pure as well as slightly contaminated products up to 500 cP. They are often used as process pump for the colouring of textiles, for water treatment but also for handling solvents, alcohols and chemicals.

NP60 benefits pump

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: easy to clean

- Easy construction and easy maintenance: less downtime

- Easy to install

- Solid impellers compared to low-cost spot welded versions

NP60 Description

The Packo stainless steel centrifugal pumps of the NP60 series are a low-cost industrial pump used for handling pure as well as slightly contaminated products up to 500 cP. They are often used as process pump for the colouring of textiles, for water treatment but also for handling solvents, alcohols and chemicals.

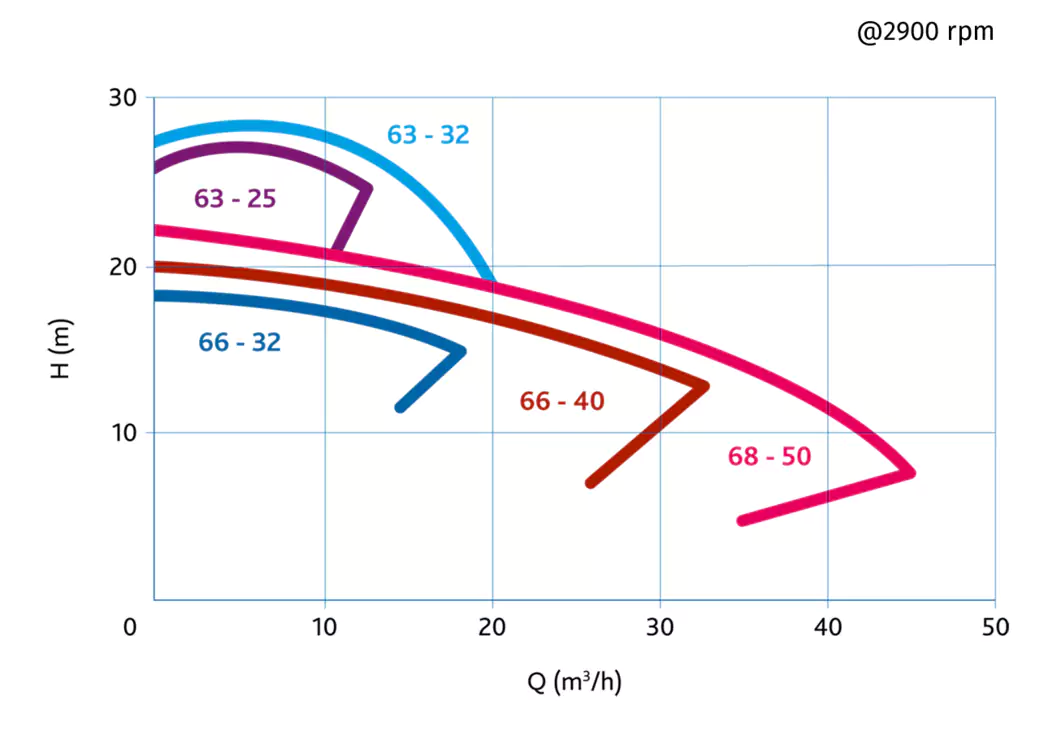

NP60 Curve

Overview of technical data NP60

| Max. flow | 40 m3/h |

| Differential head | 27 m wc |

| Max. Inlet pressure | 3 bar |

| Viscosity | 500 cP |

| Max. temperature | 95 °C |

| Impeller type | Open |

| Max. free passage | 15 mm |

| Max. drive power | 2.2 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single, quench |

| Available O-ring Materials | EPDM, FKM |

| Connections | BSP fittings. flanges according to EN1092-1/02. smooth tubes |

| Surface finish | Industrial, internal welds not hand polished, electropolished |

| Certificates | ATEX. MEI. EAC |