About mechanical seal bc

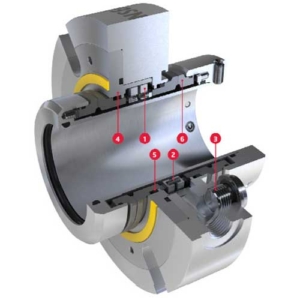

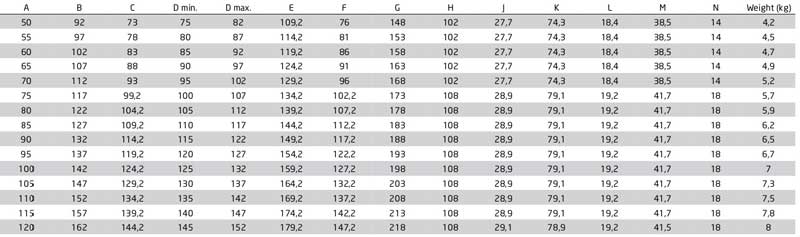

The Huhnseal BC-series is a new type of seal designed for various heavy duty applications where durability is key. This is a robust, reliable and cost effective seal suitable for standardization in larger process industries but also for customers with more limited amounts of equipment.

During the development of the BC-series the main focus has been on adaptability to different pressure and speed conditions, reliability and ease of installation. The BC is a double balanced seal that handles pressure drops on either product or barrier/buffer sides and effectively minimizes heat generation at the seal faces.

Operating range mechanical seal bc

- Pmax = 40 barg

- Tmax = 200°C

- Vmax = 35 m/s

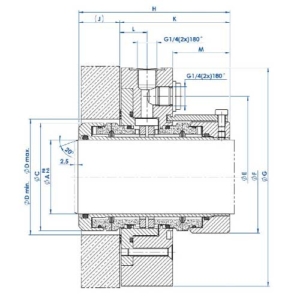

- Axial movement: ±2,0 mm

characteristics mechanical seal bc

- Designed to fit most standard equipment

- Suitable for standardizing

- Robust and durable design

- Ability to handle pressure fluctuations Easy to install

Features mechanical seal BC

- Cartridge seal for easy assembly

- Minimized built-in dimensions, fits in most standard stuffing box spaces

- Double balanced design for minimum heat generation

- Excellent pressure adaptability properties due to its double balancing

- Suitable for standardizing

- Premium materials

- Easy and time efficient to recondition on site when required

- Barrier fluid spring cleaning circulation system to minimize risk for clogging

- sintered Silicon Carbide (resistant to pH-1-14) is standard

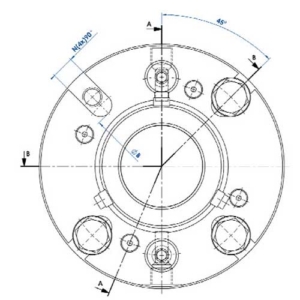

- Axial and/or horizontal barrier fluid connectivity for assembly in confined spaces

Applications mechanical seal bc

- Clean fluids

- Fluids with poor lubrication capabilities

- Crystallizing fluids

- Fluids reacting with air

- Sedimentary fluids

- High temperature fluids (>100º)

- Fluids hazardous to health and enviroment

- Extra need of cooling/pressure balancing

Excellent axial movement

The seal can move ± 2,0 mm independent of the compression of springs. The seal follows the movement of the shaft without influencing the compression of springs. This feature is essential when sealing equipment with flexible bearing units.Spring package is kept clean by the flushing

The springs are located in the area circulation and the exchange of barrier fluid is the greatest. This eliminates the risk for clogged-up springs, which is one of the most

common causes for seal failure.Adaptable flushing connectivity

Four different ways to connect the flushing media to the flange. Axially, horizontally or a mix of both.

This feature facilitates the installation of the seal in confined spaces and allows for obstructing equipment to be bypassed.Inovative inverted flange/cover design

The flange configuration with imboard cover. This reduces the cost of the seal by lowering the amount of expensive material potentially in contact with abrasive or corrosive media.Clever double balancing

The seal is double balanced using a “floating” o-ring design. This enables the seal to handle sudden pressure variations. This also makes it possible to reduce heat generation.Symetric design optimized for standardization

The seal faces used on the product side can also be used on the atmospheric side. This allows for all internal parts to be used on both sides for high standardization purposes