About Pump 2cdx

Twin impeller centrifugal pump in AISI 304 and AISI 316 stainless steel, with radial impeller and components made by the hydroforming process that provides high resistance to corrosion, high efficiency with over 80% performance and low losses. The versatility of these electric pumps is due to the different types of mechanical seals that can be applied

Features

- Compact dimensions

- Sturdy construction

- Available in AISI 316

Technical

- Total head from 71.5 to 27 m

- Flow rate 1.2 to 12.6 m3/h

- IE3 high efficiency motors starting from 0.75 kW

- Liquid temperature:

-5°C ÷ +60°C for standard and E versions

-5°C ÷ +110°C for H, HS, HW e HSW versions

description Pump 2cdx (l)

Twin impeller centrifugal pump with hydraulics in AISI 304 and AISI 316 stainless steel, with radial impeller, with hydraulics entirely in pressed AISI 304 or AISI 316 (L version).

The double impeller makes for a wider performance range than the single-impeller version.

The components of the 2CDX(L) electric pump are obtained through the renowned hydroforming process, which guarantees sturdiness, hydraulic efficiency and reliability.

The process uses a high-pressure fluid (up to 1200 bar) to form the metal.

The hydraulic fluid, in our case water, with increasing pressure pushes the stainless steel to copy the shapes of the template until it comes into contact with the internal walls of the matrix that forms the mould.

This exclusive system, which combines the power of a press with the force of water, has significant advantages over traditional processes:

- Perfectly smooth shape

- Highly smooth running

- No welding points

These features ensure high corrosion resistance, high efficiency with performance of over 80% and low leakage.

2CDX(L) electric pumps, thanks to their small size, can be positioned even in narrow or difficult to reach spaces.

The versatility of these electric pumps is due to the different types of mechanical seals that can be applied.For further technical information see the Databook

- Domestic pressurisation

- Small-scale garden irrigation

- Washing

- Water treatment

- Cooling towers

- Handling of clean water in general

Overview of technical data 2cdx

| Flow rate | from 1.2 to 12.6 m³/h |

| Total head | From 71.5 to 27 m |

| Max. working pressure | 8 bar |

| Max. temperature of the liquid | -5°C ÷ +60°C for 2CDX(L) std and E versions -5°C ÷ +110°C for H, HS, HW, HSW versions |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump 2cdx

| Pump body | Stainless steel AISI 304 (EN 1.4301) (2CDX) Stainless steel AISI 316 (EN 1.4401) (2CDXL) |

| Impeller | Stainless steel AISI 304 (EN 1.4301) (2CDX) Stainless steel AISI 316 (EN 1.4401) (2CDXL) |

| Shaft | Stainless steel AISI 304 (EN 1.4301) (2CDX) Stainless steel AISI 316 (EN 1.4401) (2CDXL) |

| Mechanical seal | Standard = Ceramic/Carbon/NBR H = Graphite/Ceramic/FPM HS = Silicon Carbide/Silicon Carbide/FPM HW = Tungsten Carbide/Tungsten Carbide/FPM HSW = Silicon Carbide/Tungsten Carbide/FPM E = Graphite/Ceramic/EPDM |

| Motor support | Aluminium (up to and including 1.5 kW), cast iron (2.2 kW and above) |

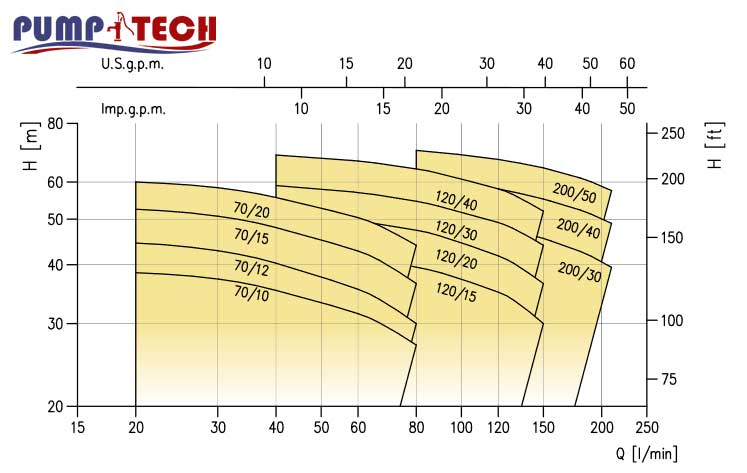

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity of = 1 mm2/s (1 cSt)

The NPSH curve is an average curve obtained in the same conditions of performance curves.

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

| Pump type | KW | Capacitro | Absored Current (A) | Q=Capacity | ||||||||||||

| 1PH 230V | 3PH 230/400V | µF | Vc | Single-phase | Three-phase | l/min | 20 | 40 | 60 | 80 | 120 | 150 | 180 | 210 | ||

| 230v | 400v | m/h | 1.2 | 2.4 | 3.6 | 4.8 | 7.2 | 9 | 10.8 | 12.3 | ||||||

| H=Total head | ||||||||||||||||

| 2CDX M 70/10 | 2CDX M 70/10 | 0.75 | 20 | 450 | 6.0 | 4.0 | 2.3 | 38.5 | 35.3 | 31.5 | 27 | |||||

| 2CDX M 70/12 | 2CDX M 70/12 | 0.9 | 31.5 | 450 | 7.0 | 5.0 | 2.9 | 44.5 | 40.3 | 35.5 | 30 | |||||

| 2CDX M 70/15 | 2CDX M 70/15 | 1.1 | 35 | 450 | 8.0 | 5.6 | 3.2 | 52.5 | 48 | 42.8 | 36.5 | |||||

| 2CDX M 70/20 | 2CDX M 70/20 | 1.5 | 40 | 450 | 9.9 | 7.0 | 4.0 | 60 | 55.6 | 50.4 | 44 | |||||

| 2CDX M 120/15 | 2CDX M 120/15 | 1.1 | 35 | 450 | 8.3 | 5.6 | 3.2 | 42 | 41 | 39.5 | 35 | 30 | ||||

| 2CDX M 120/20 | 2CDX M 120/20 | 1.5 | 40 | 450 | 10.2 | 7.0 | 4.0 | 51.5 | 49.5 | 47.4 | 41.8 | 36.5 | ||||

| 2CDX M 120/30 | 2.2 | 8.7 | 5.0 | 59 | 57 | 54.6 | 49.2 | 44 | ||||||||

| 2CDX M 120/40 | 3.0 | 10.8 | 6.2 | 68.5 | 66.5 | 64 | 58 | 52 | ||||||||

| 2CDX M 200/30 | 2.2 | 10.4 | 6.0 | 52 | 50.8 | 48.1 | 45.5 | 42.7 | 39.5 | |||||||

| 2CDX M 200/40 | 3.0 | 11.4 | 6.6 | 62.5 | 61.1 | 58 | 55.2 | 52.3 | 49 | |||||||

| 2CDX M 200/50 | 3.7 | 15 | 8.7 | 71.5 | 70.1 | 67 | 64.3 | 61.2 | 57.5 | |||||||